Comparing Silicon and Multilayer Ceramic Capacitors (MLCCs)

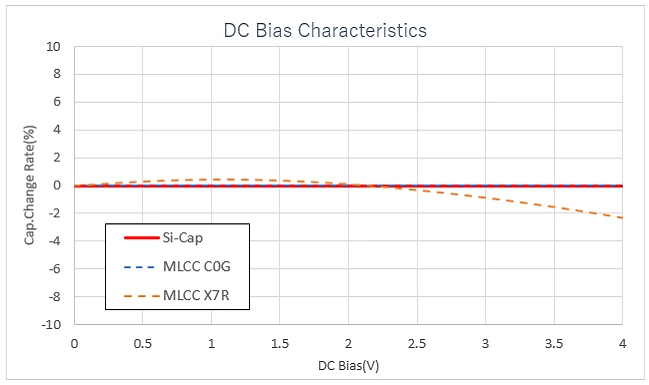

DC Bias Characteristics

The capacitance of silicon capacitors remains virtually unchanged even when voltage is applied, ensuring stable capacitance.

In contrast, although MLCCs feature similar characteristics to silicon capacitors in terms of temperature compensation, for high dielectric constant types the capacitance decreases significantly with applied voltage.

Therefore, when using high dielectric constant MLCCs, it is necessary to take into account this decrease in capacitance due to applied voltage in designs.

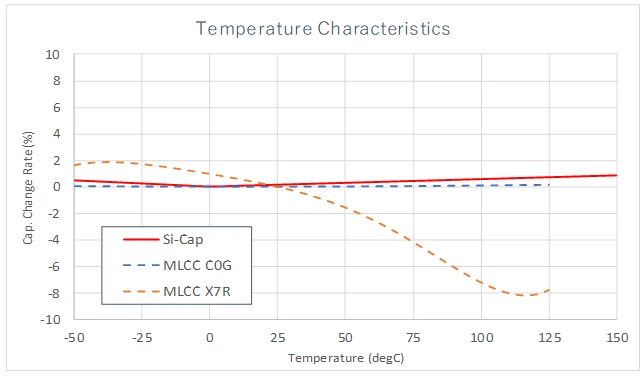

Temperature Characteristics

The capacitance of silicon capacitors remains largely unchanged even with changes in temperature, ensuring stable capacitance.

However, although MLCCs feature similar characteristics to silicon capacitors with respect to temperature compensation, the capacitance of high dielectric constant types changes significantly with temperature.

So when adopting high dielectric constant MLCCs, it is important to consider the change in capacitance due to temperature.

Silicon capacitors also have a wider operating temperature range than general MLCCs, providing stable capacitance even at higher temperatures.

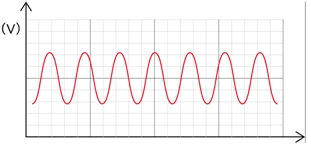

Ringing Noise

Ringing noise is often discovered during final product evaluation, requiring prompt action before the set is sold, as it can cause significant damage.

However, as silicon capacitors do not resonate themselves, there is no need to worry about noise.

Because ceramic capacitors use piezoelectric elements, voltage fluctuations can cause the capacitor to vibrate in various directions, leading to ringing noise due to resonance of the capacitor itself and base substrate.

An effective measure is to

switch to

silicon capacitors

Silicon capacitors have no piezoelectric properties

Therefore, there is no ringing problem caused by the product resonating due to voltage fluctuations.

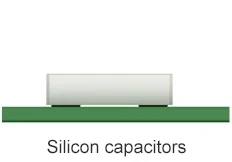

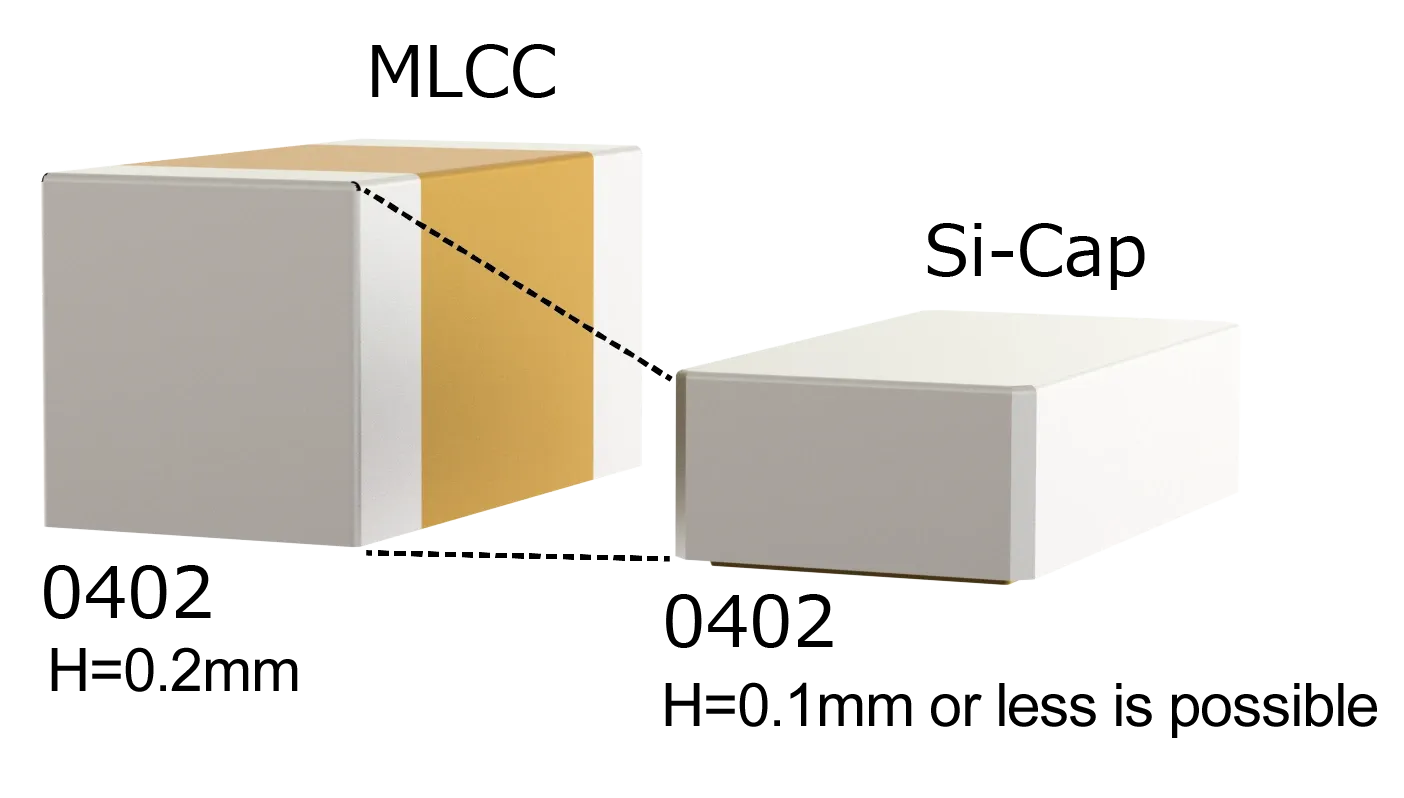

Product Height

Silicon capacitors can achieve a lower profile by forming planar and trench structures using thin-film semiconductor technology.

For example, a product height of 0.1mm or less is possible in the 0402 size (0.4mm x 0.2mm).

On the other hand, MLCCs are comprised of stacked sheets printed with internal electrodes to increase capacitance, making it difficult to reduce height.

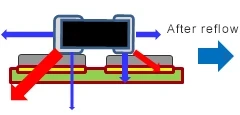

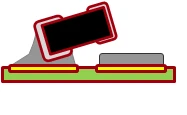

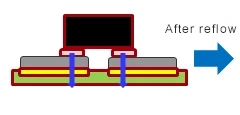

Tombstoning During Mounting (Manhattan Effect / Standing Chip)

The phenomenon whereby the chip stands up during mounting is commonly referred to as the Manhattan effect or tombstoning.

This can be attributed to a variety of factors, including variations in the amount of solder, timing discrepancy in solder melting, and misalignment of the product during mounting.

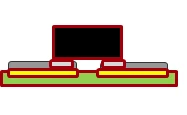

Utilizing a bottom electrode structure, silicon capacitors lack side electrodes and so are not pulled horizontally, making them less prone to tombstoning during reflow.

However, MLCCs feature a multi-sided electrode structure that causes the product to be pulled horizontally.

This can lead to tombstoning during reflow due to the above-mentioned reasons.

MLCC : Multi-sided electrode structure

As the sides and bottom are pulled by solder, force is generated in the direction of the red line. In the case of multi-sided electrodes, the difference in contact area between the electrodes and solder can become quite significant.

If the variation is too large, the electrodes will be pulled in the direction of the red line - towards the side with the larger contact area - which can lead to tombstoning.

Silicon capacitor : Bottom electrode structure

Since there are no electrodes on the sides, force only acts in the directly below the board.

The bottom electrode design reduces the likelihood of tombstoning.