Thin-Film Piezo MEMS Foundry

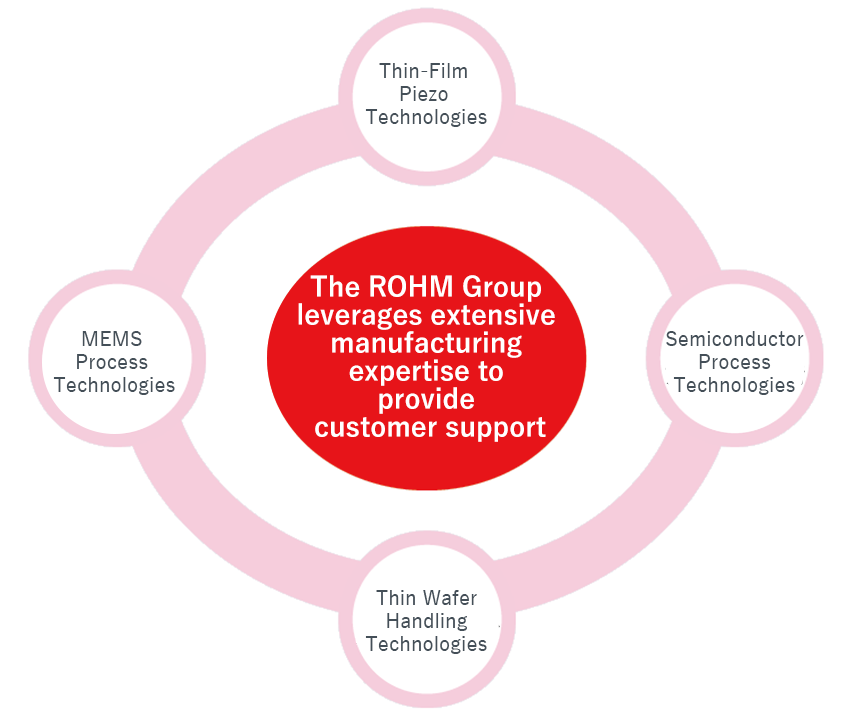

In addition to conducting R&D for many years, ROHM is focused on technological innovation using ferroelectrics. ROHM's thin-film piezo MEMS foundry utilizes in-house high reliability production equipment leveraging market-proven ferroelectric expertise along with a heterogeneous material management system that makes it possible to integrate thin-film piezoelectric MEMS and IC microfabrication technologies. At the same time, joint development allows customers to achieve next-generation solutions featuring breakthrough miniaturization with unprecedented energy savings and performance.

What is ‘piezo’? What is MEMS? -Electronic Basics

Here we explain the basics, characteristics, applications, structures, and properties of piezo and MEMS.

Development / Production Contracting

Main Technologies and Services

We provide comprehensive support from prototyping and development to mass production, including process planning for MEMS devices using silicon and SOI wafers, manufacturing high-performance piezoelectric films, and subcontracting and design support for piezoelectric MEMS devices. Feel free to contact us to discuss individual processes not listed on our website or catalogs.

Thin-Film Piezo Technologies

- ・Sol-gel PZT

- ・PZT Doping

- ・Crystallinity Control, etc.

Semiconductor Process Technologies

- ・Lithography

- ・Etching

- ・Sputtering, etc.

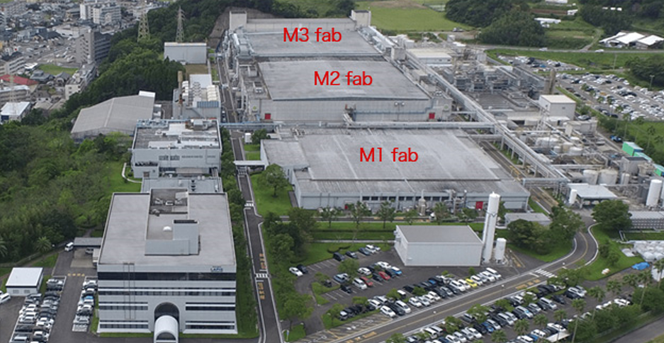

Mass Production and Development Line

A 6-inch MEMS line is being built at LAPIS Semiconductor’s Miyazaki Plant that integrates proprietary thin-film piezo technologies into an LSI production line.

| Location | Kiyotake-cho, Miyazaki City, Miyazaki Prefecture, Japan |

|---|---|

| Clean Room | 1,360m2 dedicated to Piezo MEMS |

| Clean Rating | Class 1-1,000 |

| Wafer Diameter | 6-Inch |

| Services Provided | Engineering samples, mass-production |

| ISO Certifications | ISO9001, ISO14001 |

| Development / Production Experience | Actuators, sensors |

| Process Technologies | PZT piezo thin film, double-sided Si processing, wafer-to-wafer bonding |

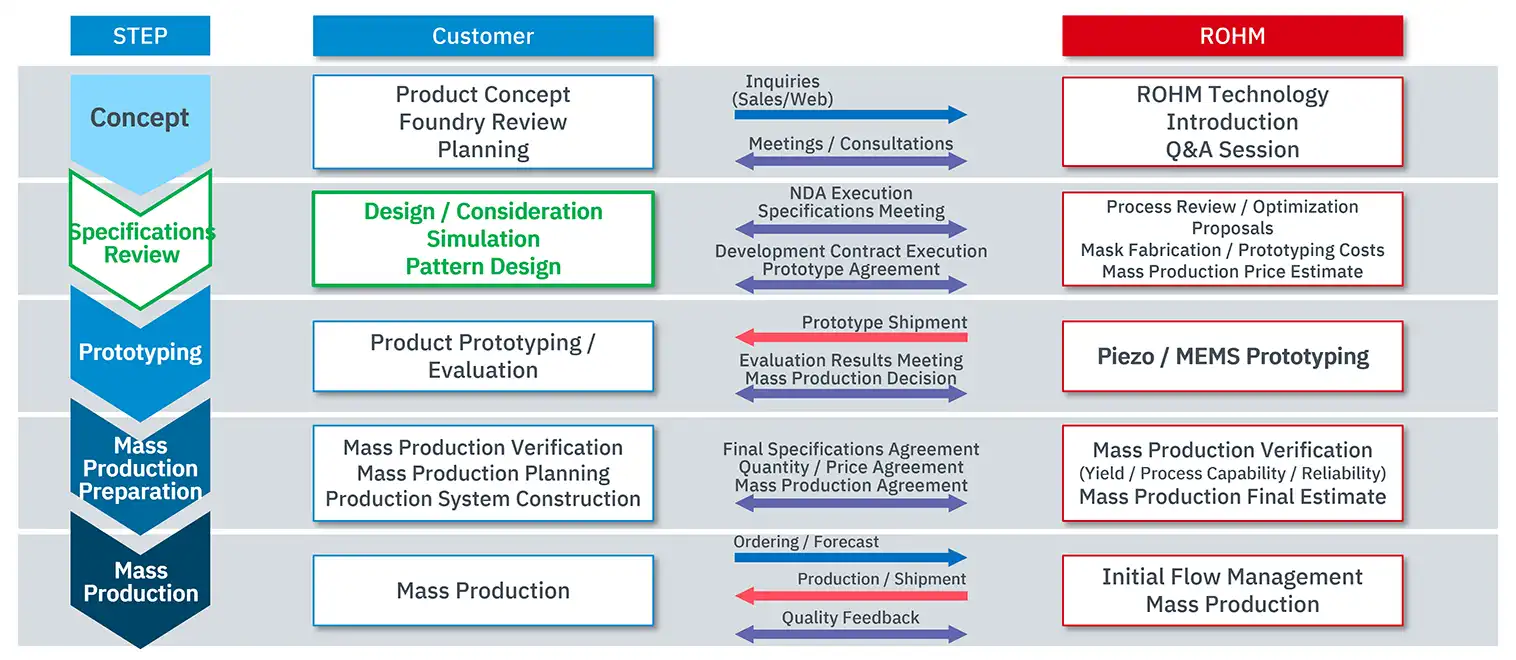

Flow from Customer Consultation to Mass Production

Our foundry with dedicated MEMS line allows us to handle everything from prototyping to mass production of customer products.

*The above flow is just an example. The actual flow will be determined after consultation in each case.

For inquiries, requests, and/or consultation, please feel free to fill out the form on the contact page.

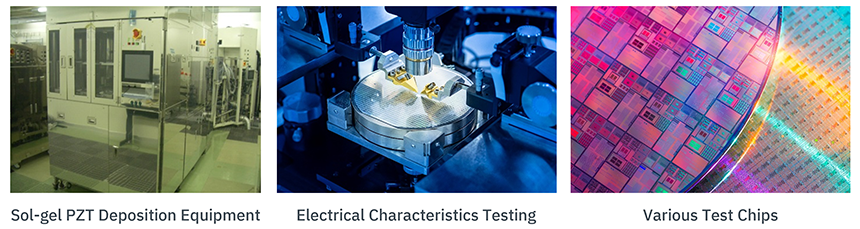

In-House Equipment

By installing the necessary equipment and analysis tools for MEMS processes in our manufacturing line, we can propose processes for a wide range of devices and initiatives to improve quality.

| Process Category | Equipment |

|---|---|

| Deposition | |

| Sol-gel (PZT) | |

| PE-CVD (SiO2, SiN) | |

| LP-CVD (SiO2, SiN, poly-Si) | |

| Thermal Oxide Furnace | |

| Sputter (Pt, Ir, IrO2, AlCu, Ti, TiN, etc.) | |

| ALD(Atomic Layer Deposition) (Al2O3, SiO2, Ta2O5) |

|

| Water-Repellent Coating Formation | |

| Photolithography | |

| Resist Coating / Development | |

| MPA (Mirror Projection Aligner) | |

| Double-Sided Aligner, IR Stepper, i-Line Stepper | |

| Dry Etching | |

| Si Deep Etching | |

| Isolation Layer RIE Equipment | |

| PZT / Electrode ICP Etcher | |

| Wet Etching | |

| SiO2 Etching | |

| Au Etching | |

| Si Anisotropic Etching | |

| Wafer Bonding | |

| Resin Bonding | |

| Anodic Bonding |

| Process Category | Equipment |

|---|---|

| Tape Lamination | |

| Automated Wafer Tape Bonding Machine (UV Tape, Thermal Release Sheet, Polyimide, etc.) |

|

| Stripping and Cleaning | |

| Asher | |

| Organic / Polymer Stripper | |

| Acid Cleaning, Scrubber | |

| Dividing, etc. | |

| Dicing, Two-Fluid Cleaning | |

| Circle-Cut Dicer | |

| Measurement | |

| Analysis / Measurement SEM, Ion Milling | |

| Optical Measurement Equipment | |

| Front / Back Misalignment Measurement Equipment | |

| Visible Light / IR / Laser Microscopes | |

| X-Ray Diffractometer | |

| Laser Displacement Measuring Device | |

| X-Ray Fluorescence (XRF) Analyzer | |

| Needle / Optical Interference Type Step Gauges | |

| Ellipsometer | |

| Automated Visual Inspection Equipment (Compatible with Front/Back Through-Wafers) | |

| Electrical Characteristics Evaluation Devices (i.e. Probes, Testers) |

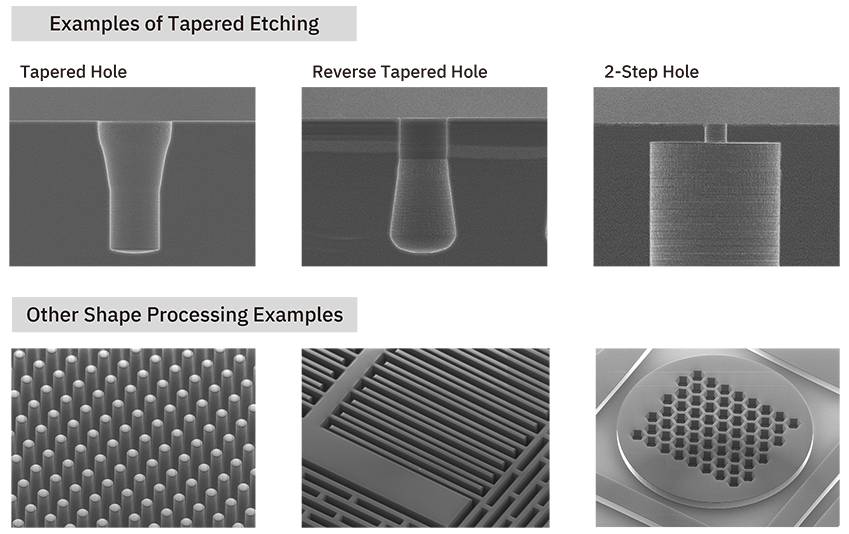

Process Capabilities

Feel free to contact us to discuss individual processes not listed on our website or catalogs.

| Process | Process Specifications | Value | Comments |

|---|---|---|---|

| Photolithography | Minimum Line Width (with Stepper) Minimum Line Width (with Aligner) |

1μm 3μm |

|

| Si Deep Etching | Taper Angle Etching Rate In-Plane Uniformity Dimensional Accuracy |

90+/−1˚ ≤5% +/−0.1μm (Both are pattern-dependent) |

Through-Substrate Processing Possible Processing on Both Sides (Front / Back) Enabled (Notch-free) Optional Taper Control |

| TMAH Etching | Depth | ≤In-plane 5% | Through-Substrate Processing Possible Processing on Both Sides (Front / Back) Enabled |

| PZT Deposition | Film Thickness Accuracy | In Wafer: +/−1.0% Between Wafers/Lots: +/−2.5% |

Doping Ex. (Nb, La) |

| PZT Etching | Processing Line Width Accuracy Etching Rate In-Plane Uniformity |

+/−1μm ≤5% (PZT thickness −3μm, tapered shape available) |

Pt stop enabled |

| Sputtering | Thickness Uniformity | ≤In-plane 4% | Pt, Ir, IrO2, AlCu, Ti, TiN, etc. |

| CVD | Thickness Uniformity | ≤In-plane 4% | SiO2, SiN |

| ALD | Thickness Uniformity | ≤In-plane 5% | Al2O3, Ta2O5, SiO2 |

| Resin Bonding | Alignment Accuracy Resin Thickness |

+/−5μm 1 to 3μm |

Epoxy, BCB |

| Anodic Bonding | Internal Seal Pressure | >0.01Pa | Si / Glass |

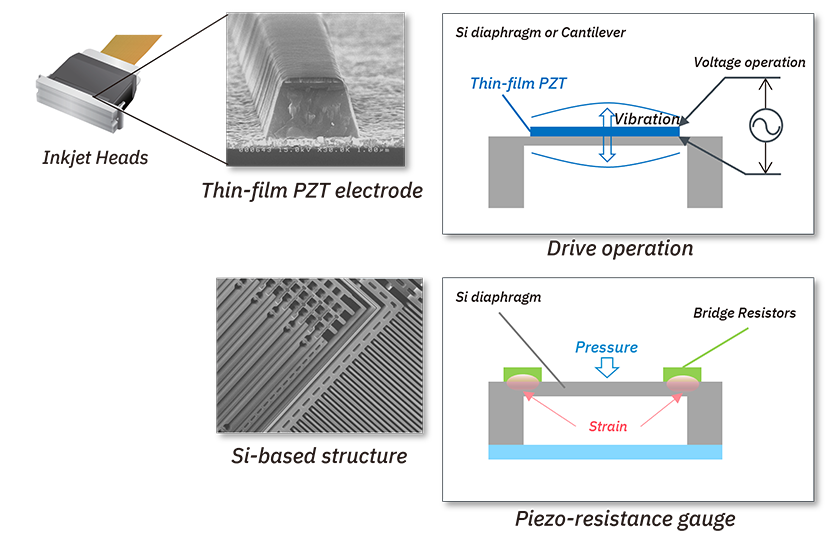

Examples of Prototypes / Mass Production Results

Leveraging experience in mass-producing inkjet heads along with expertise in MEMS technology allows us to collaboratively develop and evaluate prototype actuator devices requiring low power consumption and high displacement in a compact size.

Process Technology Examples

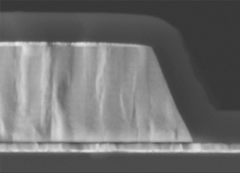

PZT Film Performance

[PZT Stack Cross-Section]

In 1998 ROHM was the first in the world to successfully mass produce ferroelectric memory.

We also possess many years of experience and expertise in the use of thin-film on silicon wafers.

The result is a sol-gel PZT film (deposited using in-house equipment) that achieves industry-leading piezoelectric performance and reliability.

| Parameter | Value | Conditions |

|---|---|---|

| Piezoelectric Constant e31, f (−C/m2) | 19 | 10V/μm |

| Inverse Piezoelectric Constant d31 (−pm/V) | 260 | 10V/μm |

| Isolation Voltage (V/μm) | >75 | Room temperature (Restricted due to evaluation power supply) |

| Isolation Life (years) | >10 | 20V/μm, 105˚C, (Estimation via acceleration testing) |

| Repeat Life (times) | >1x1010 | 10V/um, displacement reduced 10% (Unipolar pulse) |

| Leakage Current Density (A/cm2) | <1x10−7 | 20V/μm |

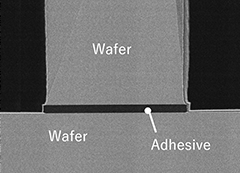

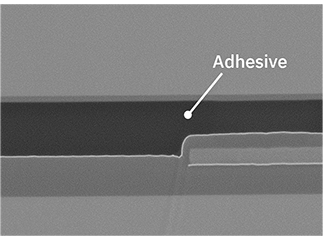

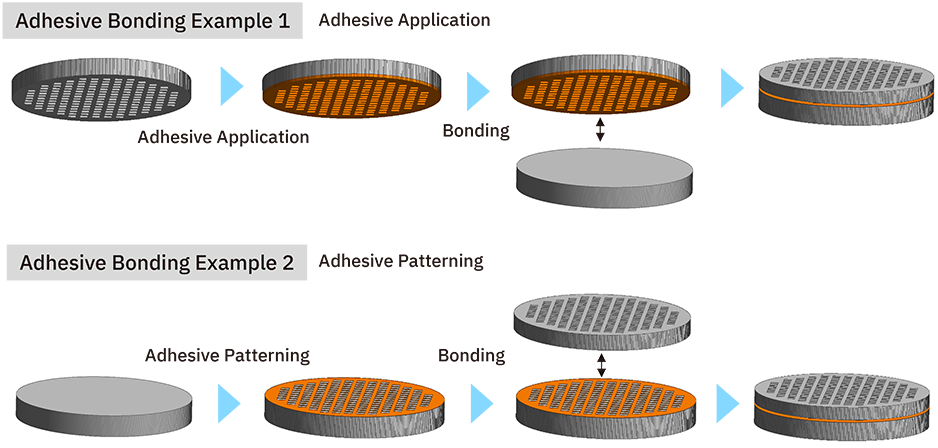

Wafer-Level Bonding Technology

[Wafer Bonding Cross-Section]

[Wafer Bonding Cross-Section / Step Region]

Multiple silicon wafer bonding technologies allow us to perform wafer-level bonding even for devices with complex structures.

*We can propose adhesive application and bonding processes.

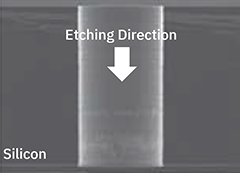

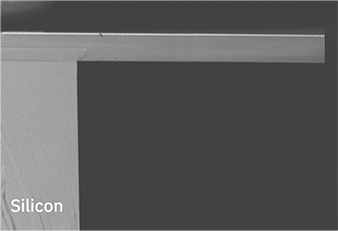

Si Deep Etching

[400μm Si Penetration]

[Silicon Wafer Processing]

We utilize multiple Si deep etching equipment from different companies (including some developed in-house) to propose the optimal Si etching process (shape, tolerance, foreign particle level, cost) for each product.

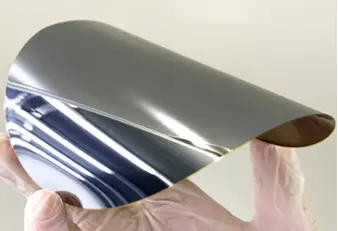

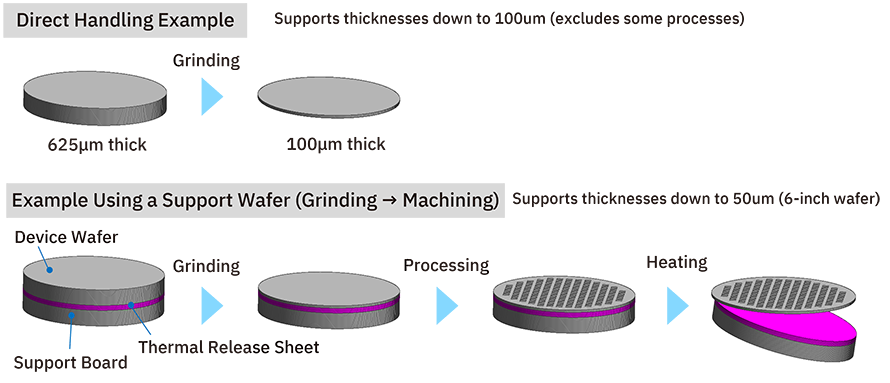

Thin Wafer Handling Technologies

[Thin Silicon Wafer]

We developed in-house wafer transport equipment that enables processing and wafer bonding using thin silicon wafers.

[TAIKO Ground Wafer]

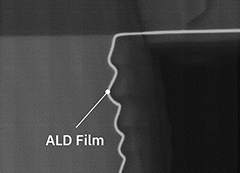

ALD Protective Film Formation

[Silicon Shaped Cross-Section]

ALD* can form a uniform protective film even on devices with complex uneven shapes.

*ALD:Atomic Layer Deposition

Protective Film: Protects devices from external factors (i.e. ink, abrasion caused by contact, static electricity).

Click here for a detailed explanation of ALD -Electronic Basics

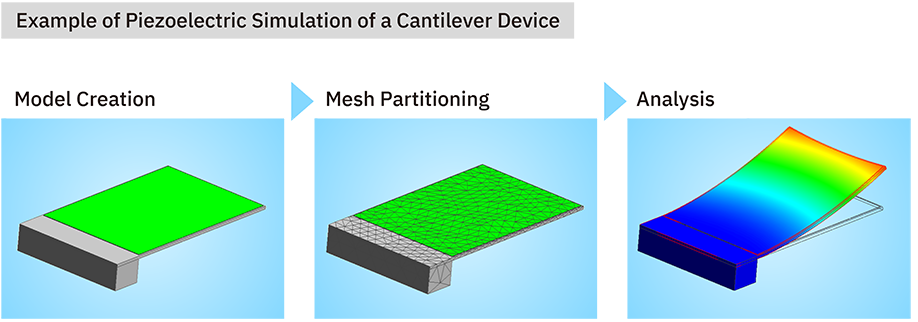

Simulation Analysis of Piezoelectric Devices

[Silicon Cantilever Cross-Section]

We can perform finite element simulations of piezoelectric devices to propose optimal structures and processes.