Silicon-carbide (SiC) Power Devices

Silicon Carbide (SiC) devices have emerged as the most viable candidate for next-generation, low-loss semiconductors due to its low ON resistance and superior high-temperature, high-frequency, and high-voltage performance when compared to silicon. SiC also allows designers to use fewer components, further reducing design complexity.

The low ON resistance of SiC devices contribute to significantly lower energy consumption, allowing users to design environmentally friendly products and systems that reduce CO2 emissions.

ROHM is at the forefront in the development of SiC power devices and modules that offer improved power-savings in applications across a number of industries.

EcoSiC™ is a brand of devices that utilize silicon carbide (SiC), which is attracting attention in the power device field for performance that surpasses silicon (Si). ROHM independently develops technologies essential for the evolution of SiC, from wafer fabrication and production processes to packaging, and quality control methods. At the same time, we have established an integrated production system throughout the manufacturing process, solidifying our position as a leading SiC supplier.

* EcoSiC™ is trademark or registered trademark of ROHM Co., Ltd.

New TRCDRIVE pack™ with 2-in-1 SiC Molded Module

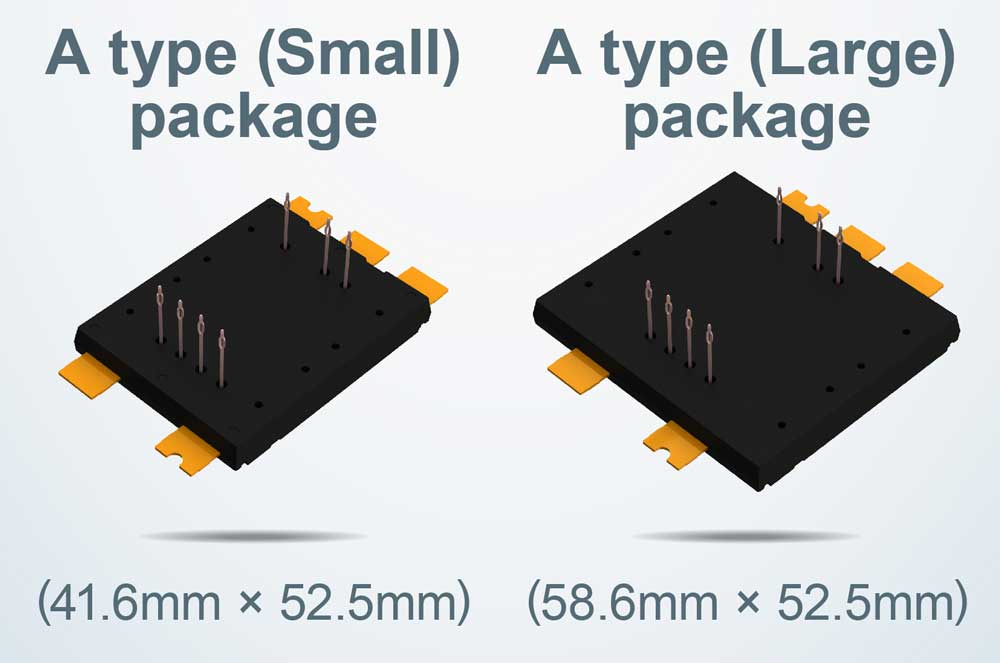

A trademark brand for ROHM SiC molded type modules developed specifically for traction inverter drive applications, TRCDRIVE pack™ reduces size by utilizing a unique structure that maximizes heat dissipation area. On top, ROHM's 4th Generation SiC MOSFETs with low ON resistance are built in - resulting in an industry-leading power density 1.5 times higher than that of general SiC molded modules while greatly contributing to the miniaturization of inverters for xEVs.

* TRCDRIVE pack™ is trademark or registered trademark of ROHM Co., Ltd.

ROHM’s 4th Generation SiC MOSFET

ROHM’s 4th Gen SiC MOSFETs contribute to drastic reductions in system size and power consumption in a variety of applications – including electric vehicle traction inverters and switching power supplies. For example, 6% electricity consumption reduction can be achieved over IGBT solutions by significantly improving the efficiency mainly in the high torque and low rotational speed range when the 4th Gen. SiC MOSFET is used in the traction inverters (calculated using the WLTC fuel economy test, an international standard).

SiC Technology Applications

Case studies and projects with customers using ROHM devices are shown here.

This application note describes the features of the 4th Gen SiC MOSFET discrete package products and explains in more detail how to obtain their maximum performance.

We confirmed its usefulness and benefit when using the 4th Generation SiC MOSFET through an experimental test using a step-down DC-DC converter a simulated running test using an EV traction inverter, and an experimental test using a Totem-pole PFC circuit were conducted.

Lineup

SiC-Related Products

ROHM is developing gate drivers optimized for driving SiC devices. Using in combination with SiC devices makes it possible to maximize characteristics. ROHM also offers ICs that integrate SiC components, such as AC/DC converter control ICs equipped with SiC MOSFETs.