Silicon Capacitor Outline

Featuring a compact, low-profile factor, silicon capacitors utilize thin-film semiconductor technology to provide stable capacitance in response to applied voltage and temperature changes.

What’s more, as there is no piezoelectric effect, no audible noise is generated due to voltage fluctuations.

ROHM also offers products with built-in TVS protection elements that ensure high ESD tolerance.

Silicon capacitors with these features are used in everything from smartphones, wearable devices, and high-speed large-capacity communication applications to automotive systems and industrial equipment.

Please refer to Capacitor Types and Characteristics for a comparison of various models.

Classification Based on Internal Structure and Mounting Method

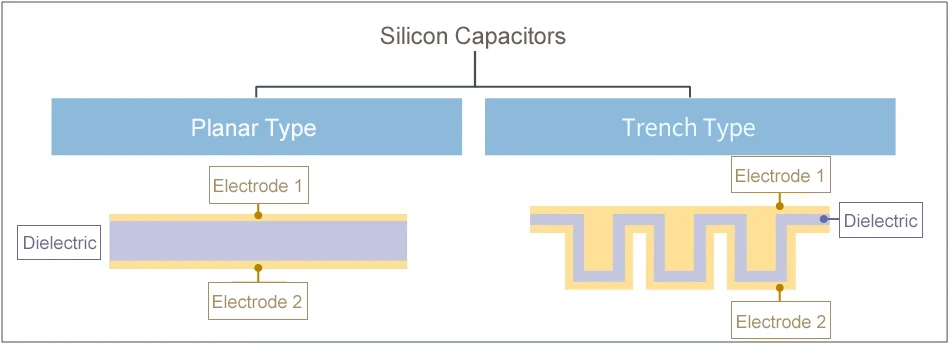

1.Classification by Internal Structure

The internal structure of silicon capacitors can be divided into two types: planar and trench.

Planar types have a simple shape that is easy to produce, making them suitable for high-voltage applications due to their uniform dielectric and electrodes.

Trench types feature a larger electrode and dielectric surface area by forming trenches (grooves) in the substrate. As a result, larger capacitances can be achieved over planar types.

ROHM focuses on compact, large capacitance trench-type products.

2.Classification Based on Mounting Method

Two mounting methods for silicon capacitors exist: solder and wire bond.

Solder mounting is suitable for high-density mounting, while wire bond mounting is ideal when integrating with ICs and other components in a single package.