Ceramic Capacitor vs Tantalum Capacitors 1

Surface mount tantalum capacitors typically feature a bottom electrode structure

Tantalum capacitors configured with electrodes on the bottom of the package are not susceptible to shorts, even when mounted close together facing each other. This makes it possible to further decrease set thickness to a level that is difficult or impossible to achieve with ceramic capacitors.

| Ceramic Capacitor | Tantalum Capacitor | |

|---|---|---|

| External Appearance |

|

|

| When Mounted |

|

|

| Limits how thin sets can become | Contributes to thinner sets |

The Strength of Tantalum Capacitors

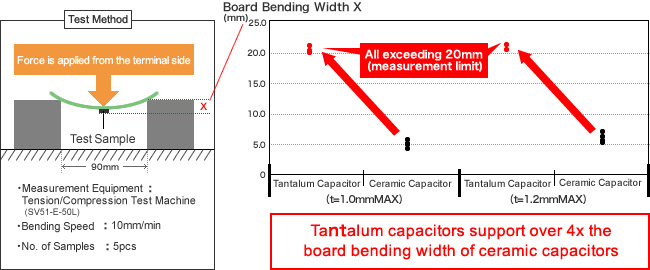

Resin-mold-type tantalum capacitors are typically strong against stress caused by board deflection. In fact, they can be mounted even at the ends of the board which are subjected to extreme deflection, providing added design flexibility. In addition, board handling precautions typically required for ceramic capacitors during assembly are not needed when using tantalum capacitors.

Board Deflection Test (2012 Size Products)