Modules and Others

Expanding our market share through new product development that leverages our proprietary technology

In the module and others (resistors) segment, because of stagnant performance, we are moving forward with reducing fixed costs and fixed assets through business organization restructuring and production site consolidation, terminating production of unprofitable products,and concentrating on high-value-added products in order to increase our profit margin. In the future, we will accelerate the development of optical modules to expand the AI server market while continuing to focus on sensor-related technology, one of ROHM’s strengths. In addition to focusing on the development of thermal printheads for barcode label printers used in the smart factory andsmart logistics field, ROHM aims to expand its share in the global market for new products that offer high speed and image quality through proprietary technology.

The resistor business continues to face harsh conditions as sales stagnate due to weak market conditions. However, our high valueadded products that we have continued to develop since around 2000 have won high praise from automobile customers, and sales of high-performance products, including anti-surge resistors and wide terminal resistors based on proprietary device designs, have been growing in recent years. While, of course, ensuring a stable supply and quality of general-purpose chip resistors, we are placing great focus on the development of special resistors that offer high performance and reliability, which will contribute to the greater performance of customers’ products.

Performance by segment

FY ending March 2025

-

■Modules

- 32.5billion yen

- 7%

-

■Others

- 25.0billion yen

- 6%

- ■ICs 203.8billion yen 45%

- ■Discrete Semiconductor Devices 187.0billion yen 42%

Sales

448.4billion yen

Sales by application

FY ending March 2025

-

Automotive

10%

-

Industrial

11%

-

Consumer

8%

-

Communication

25%

-

Computer &

Storage46%

Modules Net sales

32.5billion yen

-

Automotive

56%

-

Industrial

9%

-

Consumer

31%

-

Communication

1%

-

Computer & Storage

4%

Others Net sales

25.0billion yen

ROHM’s Position (2024)

Sales share ranking of worldwide thermal printhead manufacturers

Sales share ranking of worldwide resistor manufacturers

Key products

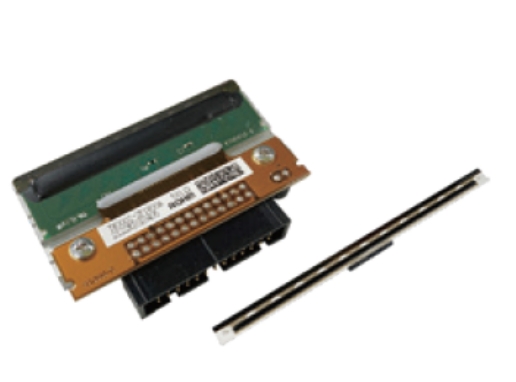

Print heads

These use ROHM’s proprietary semiconductor, thick-film printing, and thin-film deposition technologies, and are small, save energy, are high quality, and provide high image quality.

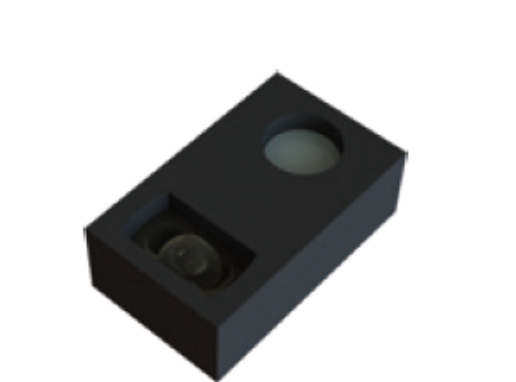

Sensor modules

ROHM can propose total solutions by combining the world’s top-level sensor variations with ROHM’s core technologies.

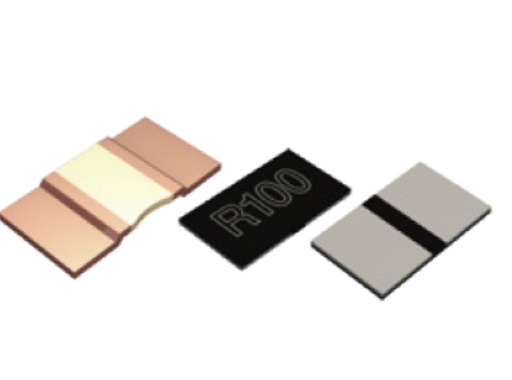

Resistors

One of the indispensable components in electric circuits, resistors work to ensure smooth operation of electric circuits. They provide high added value because they are high performance, highly reliable, and can be miniaturized.

Column|

Examples of value creation

Contributing to advances in electronic components through highly reliable high-power MCRx series even though they are compact.

ROHM considers miniaturizing and increasing the performance of electronic components as important issues on account of the diversification of electronic devices and electrification. Particularly in the automobile industry, there has been a rapid increase in the number of electronic components used as electric vehicles (xEVs) become more common. In the industrial equipment market, too, greater performance and efficiency of products have resulted in growing demand for compact, high-performance electronic components. In November 2024, ROHM introduced the new MCRS series and MCRL series as parts of the MCR series of general-purpose chip resistors to meet this demand.

The MCRS series boasts improved rated power and thermal characteristics (temperature coefficient of resistance (TCR)*1) due to optimized internal structure and use of new materials, which makes it possible to use more compact components that are one size smaller than traditional ones. The MCRL series, which is a low-resistance version of the MCRS series, is best suited for detecting electrical current. Furthermore, the MCRx series, all sizes of which are compliant with in-vehicle electronic component reliability standard AEC-Q200,*2 has contributed to the growth of various markets, including the xEV, telecommunication infrastructure (base stations, servers, etc.) and FA equipment markets. This also supports a continuous supply for uses conditioned on long useful lives, such as for products in industrial fields and infrastructure equipment.

In the future, for the MCRS series, we expect to develop compact resistors capable of operating at +155°C. As for the MCRE series, we will also start to supply more compact lead-free products. In this way, ROHM will meet the diverse needs of customers in global markets and contribute to the evolution of electronic components by strengthening our response to both the greater need for miniaturization and voluntary regulations, exports controls, and other constraints through environmental awareness.

- *1 Temperature coefficient of resistance (TRC):This is an indicator of the extent that resistance changes as temperature changes. The lower the TCR, and smaller the change in resistance due to temperature change, making it possible to offer stable performance.

- *2 These are reliability standards for in-vehicle electronic components set by the Automotive Electronics Council (AEC), which is composed of major car manufacturers and major U.S. electronic component manufacturers. Having in-vehicle components compliant with these standards ensures their reliability under harsh environmental conditions. Q200 is special standard for passive components, such as resistors, capacitors, and inductors.