Power Semiconductors of the Future: 6 Facts you should know about SiC

06/21/2021

Not long ago, silicon carbide (SiC) was an exotic material among semiconductor devices. Today, it has become more and more established in the industry and is considered to be the future of power electronics. But what are the key features of SiC and why is this material so special compared to standard silicon? Here are 6 key facts you should know about SiC:

With a few exceptions, the semiconductor sector is dominated by silicon (Si). But especially in power electronics, Si is increasingly reaching its limits, for example in terms of operation at higher temperatures, voltages and frequencies.

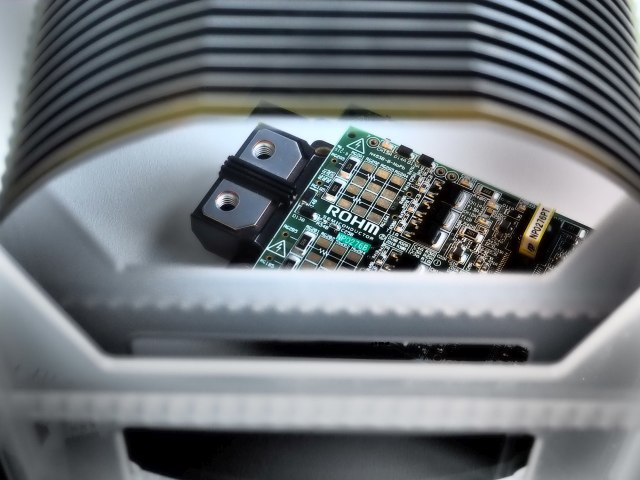

Silicon Carbide: a key material inside electric vehicles.

In components such as Schottky barrier diodes or FETs/MOSFETs in converter, inverter, power supplies, battery chargers and motor control systems, new materials such as SiC (Silicon Carbide) could provide the solution.

1. Material Properties

There are several polymorphic crystal structures of SiC, but the 4H-SiC polytype hexagonal crystal structure is best suited for high power applications.

With this structure, the semiconductor exhibits very strong physical bonds. This leads to high mechanical as well as thermal stability. Thus, SiC shows up to 10 times higher mean time to failure (MTTF) than Si.

The essential property for power electronics, however, is the band gap: At approx. 3.26eV, this is significantly larger for SiC than for Si (1.12eV). As a result, SiC is also classified as a wide bandgap semiconductor (WBG).

2. Advantages of a wide bandgap

The wider band gap also means up to 10 times higher electrical breakdown fields. Thus, components with higher breakdown voltages (600V up to several thousand volts) can be achieved. At the same time, the drift layer thickness can also significantly be reduced – enabling smaller components overall.

The drift layer thickness is the parameter that most strongly influences the on-resistance of a MOSFET. SiC therefore enables MOSFETs with lower ohmic losses, which directly improves the efficiency.

3. Temperature stability

The wider band gap also enables operation at higher temperatures: Si semiconductors can usually only be operated up to about 150°C, while SiC semiconductors have the potential of going up to even 600°C.

At the same time, SiC has a better thermal conductivity (1490 W/m·K) than Si (150 W/m·K). The material can therefore be cooled more easily and more quickly. Moreover, SiC also has a low thermal expansion and excellent thermal shock resistance.

4. Lower switching losses

In order to turn a MOSFET on and off, the gate electrode must be charged or discharged. If the required gate charges are larger, the times for charging/discharging and thus the turn-on losses also become larger. Since SiC MOSFETs can be built in smaller sizes than Si MOSFETs, their gate charge and thus their turn-on losses are also smaller.

5. High frequency operation

Higher switching frequencies enable smaller passive devices. Due to the smaller switching inductances and losses, SiC enables higher switching frequencies than Si MOSFETs.

IGBTs also have an upper limit on switching frequencies. For example, the tail current when switching off: This is caused by the trapping of charge carriers in the bipolar output section of the IGBT. This causes the device to stay on longer, which cannot be accelerated. The tail currents also mean additional turn-off losses. Since MOSFETs are unipolar, SiC MOSFETs do not have this problem.

6. Intrinsic body diode

Just as Si MOSFETS, SiC MOSFETs have an internal body diode. This is an advantage, since IGBTs need an actual diode in parallel to avoid reverse currents. One of the main limitations offered by the body diode is the undesired reverse recovery behavior, which occurs when the diode switches off while carrying a positive forward current. The reverse recovery time thus becomes an important index to define the characteristics of a MOSFET. The body diode of SiC MOSFETs is extremely fast, in fact the reverse recovery time and also the reverse recovery current are even negligible, leading to a reduced energy loss compared to Si MOSFETs.

ROHM’s 4th generation of SiC MOSFETs

ROHM’s newest generation of SiC MOSFETs achieves up to 50% lower switching loss and 40 % reduction of ON resistance without sacrificing short-circuit ruggedness. On top, the latest generation offers a more flexible gate voltage range (15 -18V) and supports turn-off with zero volt – enabling simple gate drive circuits with unipolar supply to be used. More info can be found here.

Interested to learn more about SiC? We invite you to explore the following material:

- In our new video, Dr. Robert Eckstein, CEO of SiCrystal, explains the process of SiC crystal growth and outlines the substrate’s various key features: https://www.youtube.com/watch?v=LeHE-7KmVvE

- 800V Battery or SiC Inverter in electric vehicles: What comes first?

In his new LinkedIn Pulse article our colleague Simon Oudin, Business Development Manager Car OEM, prepared two scenarios: https://www.linkedin.com/pulse/800v-battery-sic-inverter-electric-vehicles-what-comes-simon-oudin/?trackingId=umyAXX5XsVVXDnfXld9glA%3D%3D