Achieving a low-carbon society by reducing power loss!ROHM supports Takenaka Corp.

BEMS through industry-leading SiC technologies

※The contents and presenter’s titles are correct at the time of reporting(October, 2019)

※Reprinted with permission from content on the “Newswitch” by THE NIKKAN KOGYO SHIMBUN,LTD.(THE DAILY INDUSTRIAL NEWS)

Takenaka Corp.’s BEMS (I.SEMⓇ) Installed in its TAK Shinsuna Building

Energy Management for Energy-Conservation and Global Warming Countermeasures

The introduction of Energy Management Systems (EMS) that leverage sensors and IT equipment to streamline power consumption in homes and buildings is advancing amid the backdrop of global warming. And in recent years, the adoption of EMS as a BCP (Business Continuity Plan) countermeasure has been highlighted in response to the increasing use of electricity generated from renewable energy sources such as solar and wind along with the rising occurrence of natural disasters including typhoons and earthquakes.

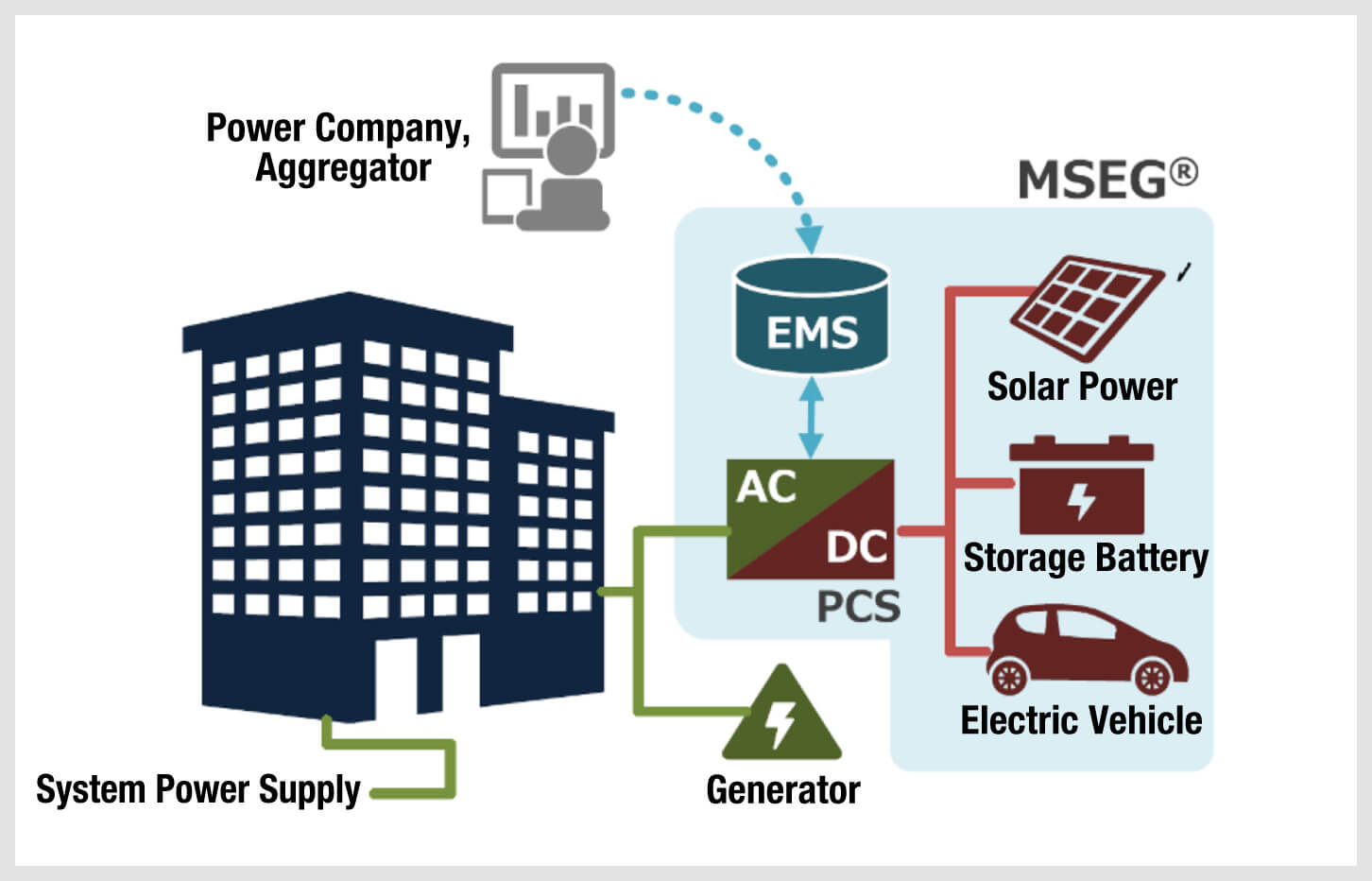

Takenaka Corp., a leading construction company, established a proprietary Building Energy Management System (BEMS), called I.SEMⓇ (I-Smart Energy Management System), at the Shinsuna HQ building of affiliate company TAK E-HVAC. Efficient operation is achieved by utilizing multiple energy sources while balancing the ever-changing factors of supply and demand. Here, ROHM’s high efficiency SiC power devices play a major role in reducing power loss.

Takenaka Corp.’s BEMS, installed in 2015 in the New Shinsuna HQ building featuring a total floor area of approx. 4000m2, consists of a system of power conditioners (PCS) that incorporate SiC power devices, charge/discharge equipment for EVs, stationary storage batteries utilizing recycled EV batteries, and generators.

Proprietary BEMS (I.SEM) Introduced by Takenaka Corp.

I.SEM involves installing solar panels on the roof of the building. The devices are controlled by providing input/output values from the BMS configured on the cloud.

‘For example, we decided to prioritize some patterns, such as giving preference to solar power and storing excess power in storage batteries and EVs,’ said Kenji Okano of the Energy Solutions Planning Group of Takenaka Corp.’s Environmental Engineering Division. ‘Optimizing the supply-demand balance by giving instructions, such as the amount of kW that must be supplied to the building at the present moment, allows the system to adjust by prioritizing system power.’

Utilizing SiC in power converters reduces loss by 40%

In a typical system comprised of silicon devices that connects individual components with AC, the large power loss in the converter itself, combined with the increased number of passes through the converter, inevitably leads to significant loss in the entire system. In response, power devices utilizing high efficiency SIC were introduced to the system adopted in the Shinsuna HQ building, arranged in a ‘micro grid’ connected to a DC bus. This system was the result of a joint development between IKS (Nakagyo-ku, Kyoto) and Takenaka Corp.

Depending on the power path, the power loss of each device can be reduced by up to 40% compared to their silicon counterparts. Furthermore, the power efficiency of the entire system has been improved by approx. 10% over the existing system. Mr. Okano added, ‘If the storage battery is charged with surplus power from solar power generation and the amount of power generated is reduced, if one decides to discharge from the battery and operate at a higher self-consumption rate, the power path becomes complicated and the number of power conversions will increase. This makes the improved power conversion efficiency of SiC particularly effective.’

The system also incorporates BCP countermeasures. At a disaster response demonstration held in 2018, continuous operation for 72 hours was achieved in a separate building (total floor area: 600m2) on the same site using emergency power supplies consisting of 2 PHEV buses and PHEVs along with system storage batteries This successfully verified the performance of its self-supporting power supply system that optimally responds to load.

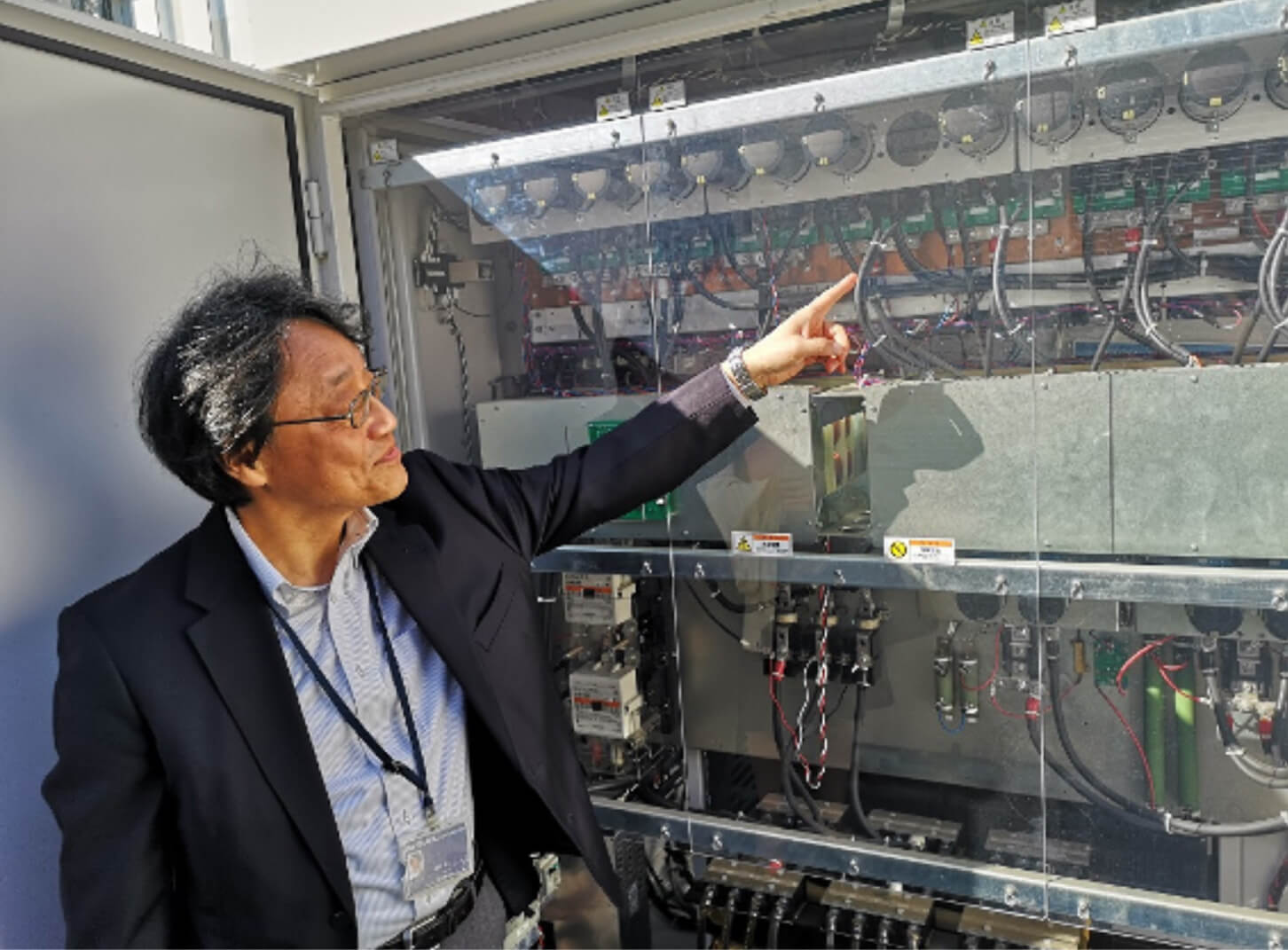

Mr. Okano of Takenaka Corp. Explains the Proprietary Power Supply System

Superior devices contribute to solving global environmental issues

Presently, Takenaka Corp. is introducing this system at other in-house facilities and customer buildings. ‘There are about 10 projects spanning both company and customer properties where this system is expected to be introduced,’ says Mr. Okano. The target for external sales is the large market of medium-sized buildings with a total floor area of approx. 10,000m2. What’s more, the system can be installed not only in new buildings, but retrofitted in existing ones as well. ‘Provided there is enough space,’ Mr. Okano explains. ‘The system can be installed in buildings with enough space for one or two cars,’ belying its excellent performance despite its small size. Although costs run in the tens of millions to install a complete system, Takenaka Corp. appeals to customers by promoting its usefulness for both BEMS and BCP.

The BEMS market is growing steadily due to the increasing demand for building construction associated with the upcoming Tokyo Olympics and Paralympics along with urban redevelopment efforts centered on Higashi Meihan. However, achieving excellent BEM requires superior components. High efficiency SiC power devices that exceed the performance of their existing silicon counterparts are expected to meet these demands and contribute to solving global environmental issues through greater energy savings.