Minimizing total consumption by using only the power needed

Achieving high power conversion efficiency is key

Does saving power always involve inconvenience?

Saving energy and protecting the global environment are essential for achieving a sustainable society. And how to effectively use power is a key factor.

There are a lot of ways to reduce power consumption. Turning off the TV, setting the AC to a higher temperature, and doing laundry in larger loads are some typical examples. To many people, these are among the first things that come to mind. And they are certainly effective for saving power. But they all involve compromise and at least some level of inconvenience.

At the same time, our dependence on electric power individually as well as society as a whole is increasing exponentially. So drastically cutting power consumption is bound to reduce the quality of life and prevent substantial growth.

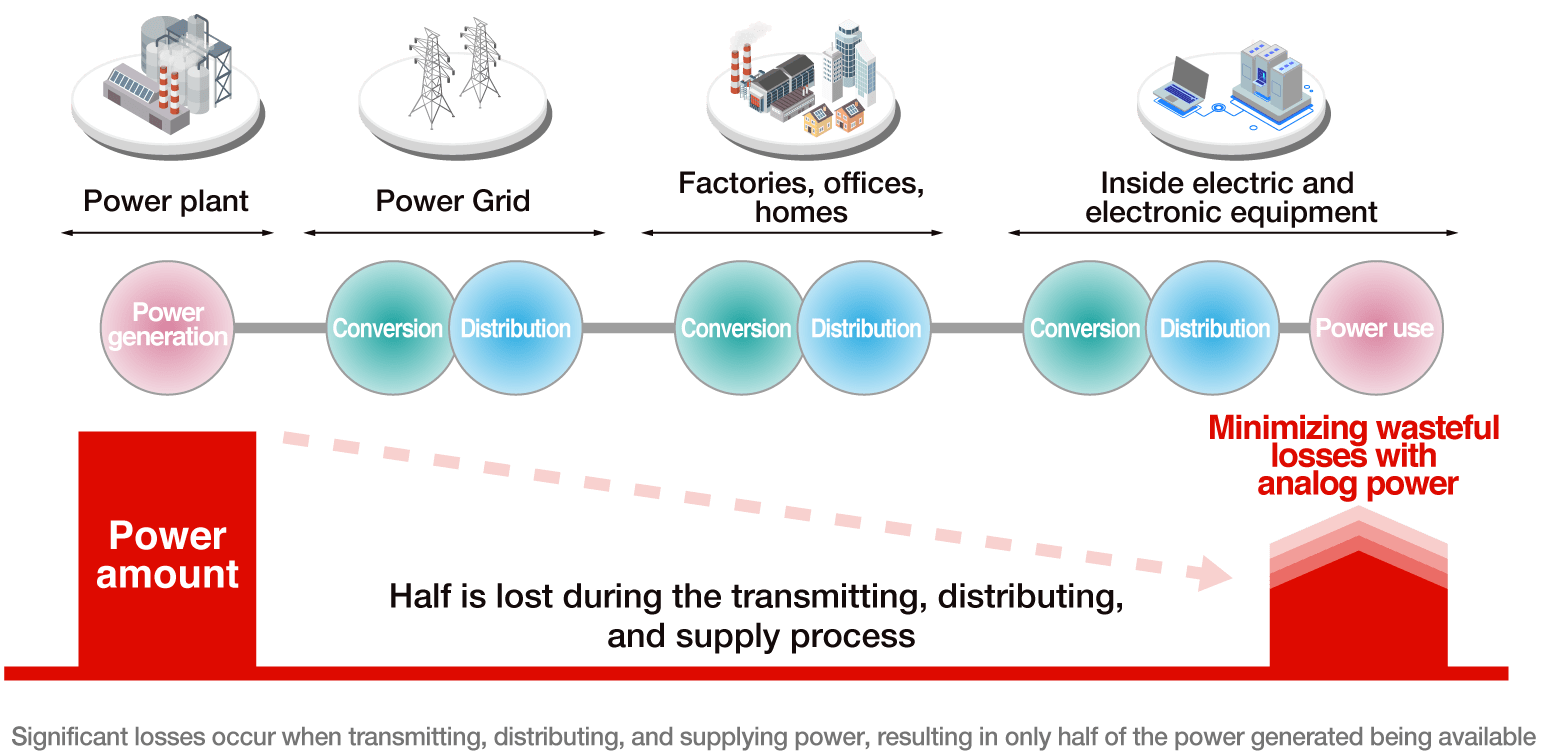

Half of all power produced is lost

Most people do not know how much of the power generated at the power plants is actually consumed by electric and electronic devices at the hands of consumers. Many will be surprised to learn that it’s only about half. The rest is lost during the process of transmitting, distributing, and supplying the power. In other words, half of all power produced by thermal power plants that burn large amounts of oil and discharge CO2 as well as nuclear plants with high maintenance risks is wasted.

We must therefore ask ourselves whether it is possible to reduce losses that occur in the process of transmission, distribution, and power supply. If losses can be minimized, significant power savings can be realized without consumers having to make compromises or restrict the use of electronic equipment. Identifying waste that occurs in the current use of electricity and systematically reducing this waste should therefore be given top priority.

Power conversion is necessary to reduce losses, but it also generates loss

The route from the power plant to consumer devices is a long one that entails transmission lines, cables, and even the internal wiring of the devices themselves. And these connections are far from straightforward. In the process of sending power there are multiple stages requiring conversion involving different specifications for voltage, frequency, and AC vs DC. These steps are necessary for reasons such as minimizing the natural loss due to the resistance of the cables and to improve handling and safety while matching the usage conditions of the internal electronic components and semiconductors. What’s more, during each conversion process 5 to 15% of power is lost.

As a result, the available power decreases with every step as it makes its way to the consumer. These losses also occur in the power grid that connects the power plants to factories, homes, and offices. And even more power is lost between the connection from the power outlet to the electronic equipment, as well as during the conversion and distribution process carried out within the device itself. For example, the heat generated by the AC adapter that powers your computer is wasted energy.

Both high and low power applications are expected to benefit from improved conversion efficiency

Equipment that handle large amounts of power, such as photovoltaic power conditioners and charging stations for EVs, utilize robust power devices rated for high voltages and currents in the power conversion circuits.

In the past, these high power devices themselves generated considerable heat during operation, causing substantial loss. Furthermore, their robustness often resulted in slower operation, making it difficult to achieve precise control equivalent to low-power devices. This therefore calls for innovation at the device level to reduce power losses during conversion.

The power consumption of electronic components and semiconductors such as MCUs and displays mounted in electronic equipment that have conventionally been driven using relatively low power is increasing at a rapid pace as well. Even so, the urgent demand for lower power consumption is an issue designers must deal with when cutting losses within devices. The most viable target is currently the power supply circuit. For this reason the efficiency of components that comprise the power supply circuit such as the power supply IC has become a major focus of attention.