Saving Energy by Improving Power Conversion Efficiency in Industrial Inverters Through Semiconductors

02/05/2024

Amid the shift towards a decarbonized society and growing expectations for renewable energy in the face of energy shortages, there is a need to improve inverter technology which holds the key to increasing energy efficiency. As such, power devices and analog ICs significantly influence the energy saving performance and efficiency of inverters. Using state-of-the-art analog ICs in the right applications can further increase inverter power converter efficiency, leading to greater energy savings by reducing power consumption in industrial equipment. Here we will explain the characteristics and features of cutting-edge power devices and analog ICs that are increasingly being adopted in the latest inverters.

Contents

- How inverters save energy

- Why more energy efficient current inverters are needed

- Power devices are the key to effective energy savings in inverters

- Characteristics and benefits of optimized semiconductors based on case patterns of issues and concerns

- 1. The need to increase conversion efficiency

- 2. Pursuing cost along with conversion efficiency

- 3. The demand for smaller, lighter equipment

- Analog ICs

- Power Supply ICs

- Gate Driver ICs

- Shunt resistors

- Summary

- Product Introduction / Detailed Information, Other Links, etc.

How inverters save energy

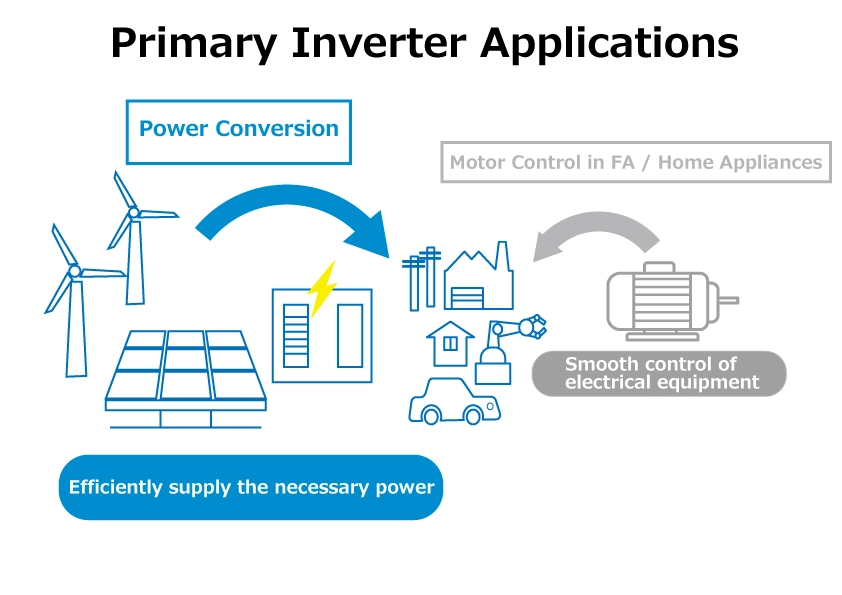

Inverters are devices that supply the necessary power by converting direct current (DC) into alternating current (AC). Efficient inverters minimize energy consumption by maximizing the performance of facilities and equipment.

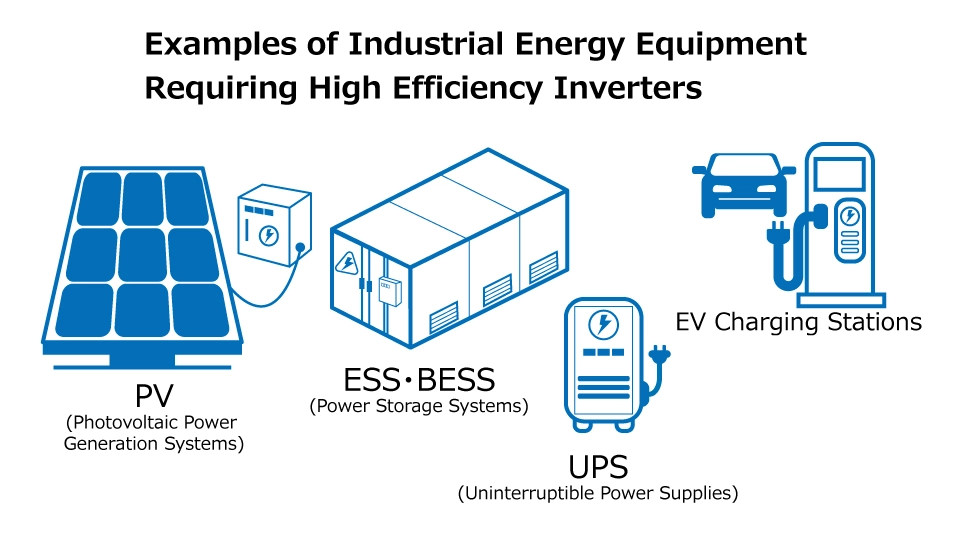

Although generally thought of as a technology for controlling motors in factory automation applications or for smoothly controlling the operation of pumps, dampers, fans, AC, and the like, another major use of inverters is the efficient conversion of electrical energy, which is key to achieving energy savings in industrial equipment. In particular, as the shift to a decarbonized society and carbon neutrality progresses worldwide, there is a growing demand for inverters that deliver excellent energy conversion efficiency in emerging markets such as charging stations and PV inverters used in solar power generation facilities. Now, let’s turn our focus to power conversion in inverters.

Inverters and related power device solutions play a central role in achieving energy savings and high efficiency in a variety of industrial facilities and equipment, such as solar power systems.

At the same time, effective inverter operation is highly dependent on advances in semiconductor technology. As such, leveraging the latest semiconductors allows inverters to achieve more efficient, stable operation. And additional benefits such as extended equipment life can be expected.

Why more energy efficient current inverters are needed

Invented in 1958, inverters first appeared in Japan in 1966.

As you can see, inverters themselves are not a new technology. In fact, many of the equipment and facilities around you likely have inverters installed.

Now, however, there is a growing trend of reevaluating the operation of inverters in facilities and equipment.

One major reason for this is the increasing amount of electricity and power being used at manufacturing sites.

Automation and smartification are currently being accelerated at many production facilities. Although each piece of equipment is becoming more energy efficient, in many cases the amount of electricity consumed as a whole is increasing.

To maximize energy-saving performance of equipment, it is necessary to implement inverters with commensurate capabilities.

Higher voltages, smaller size and lighter weight are also significant factors. For example, as solar power equipment operate at higher voltages and power conditioners become smaller and lighter, inverters that convert power are required to support these trends as well.

Power devices are the key to improving the energy saving effectiveness of inverters

Approximately 90% of power loss during power conversion in inverters can be attributed to power devices.

Therefore, it is no exaggeration to say that the performance of power devices directly affects the performance of inverters.

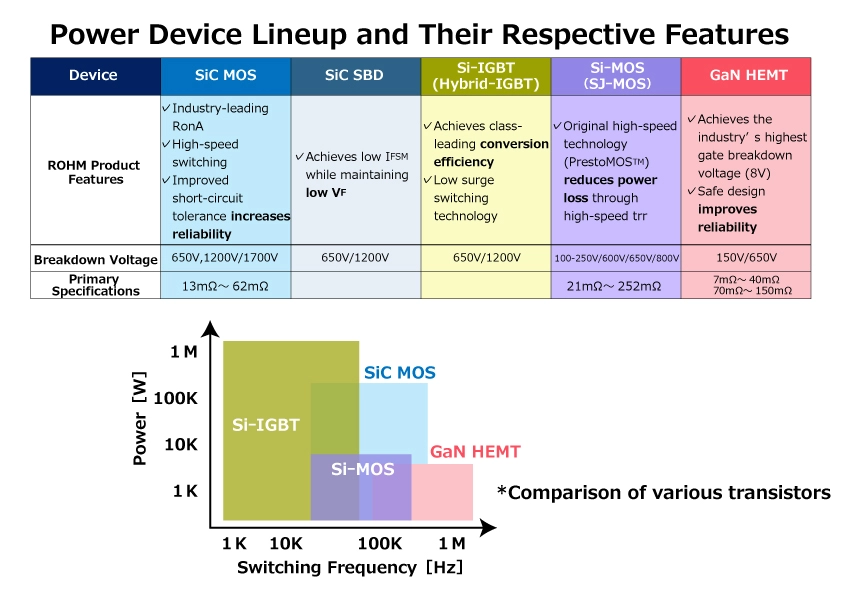

In the industrial equipment field, mainstream silicon power devices are increasingly being replaced with SiC and GaN. The same holds true for inverters.

So what power devices are best for inverters?

In reality, it is not as simple as replacing with the latest SiC or GaN devices. This is because the ideal solution depends on the size and requirements of the specific equipment. Selecting the optimal power device solution according to the equipment and application makes it possible to operate inverters with higher cost performance and excellent energy conversion efficiency. This translates to significant energy savings.

For example, ROHM’s power device lineup offers a number of features.

Features and benefits of optimal semiconductor products based on case patterns of issues and concerns

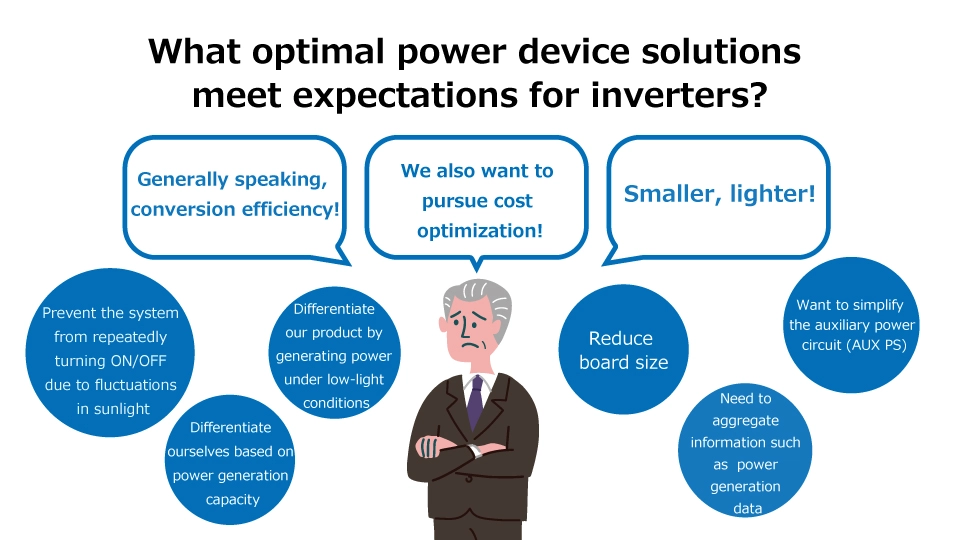

The ideal power device solution can vary depending on the inverter application and nature of the problem.

So what are the most common requests?

Due to the diverse range of specific requirements, we will introduce typical demands and the corresponding optimal power device solutions.

1. The need to increase conversion efficiency

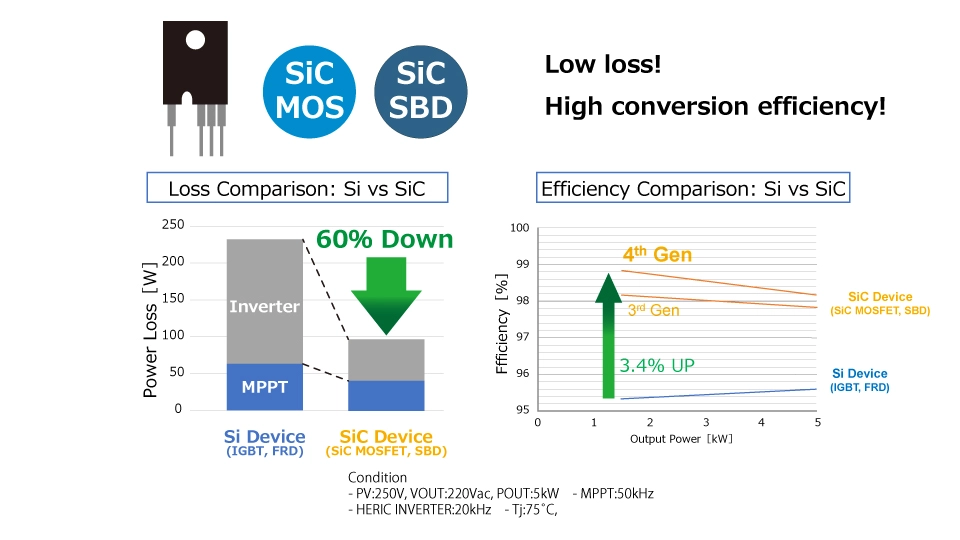

To maximize conversion efficiency and improve power generation, we recommend SiC MOSFET, SiC SBD and other SiC devices.

As SiC exhibits high breakdown voltage, low ON resistance, and high-speed switching characteristics, replacing Si devices with SiC contributes to improved power generation by increasing conversion efficiency.

For example, to improve the amount of electricity generated by a residential PV inverter at average illumination, replacing Si devices with SiC can increase the power generation capacity by approximately 3.4%, or about 45W at 1kW to 2kW (210kWH/year). At the same time, there is a growing demand for inverters that support high voltages and currents.

*Approx. 130W at 5kW power generation (570kWh/year)

2. Pursuing greater cost and conversion efficiency

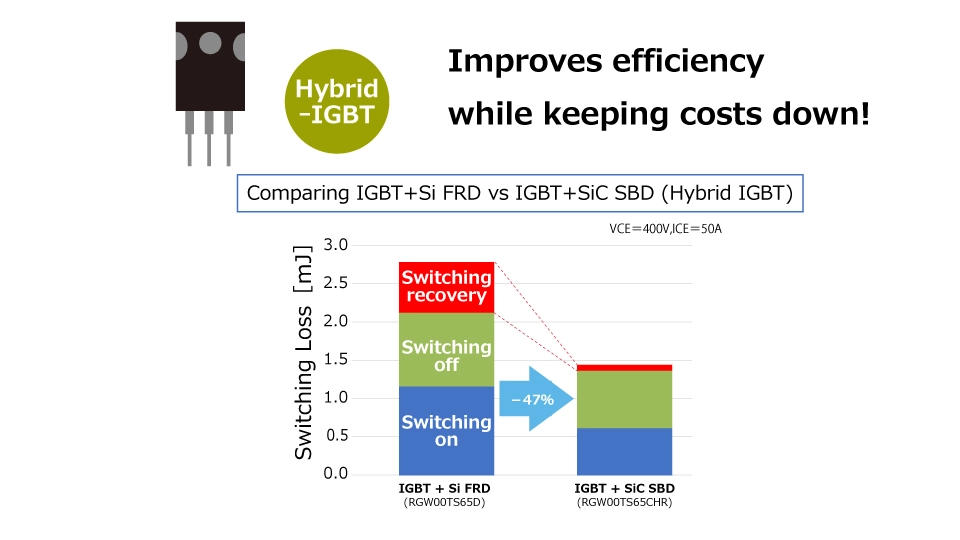

There is a growing need to increase conversion efficiency while reducing costs. Hybrid IGBTs can meet these requirements.

Hybrid IGBTs utilize ROHM’s low-loss SiC Schottky barrier diodes in the feedback section (freewheeling diode) of conventional IGBTs, resulting in significantly lower ON switching loss vs conventional IGBTs.

Developed for industrial equipment and automotive electrical systems that handle large amounts of power, such as onboard chargers and DC/DC converters in xEVs and PV inverters for solar power generation, these devices offer lower loss than their Si counterparts and better cost performance than SiC solutions.

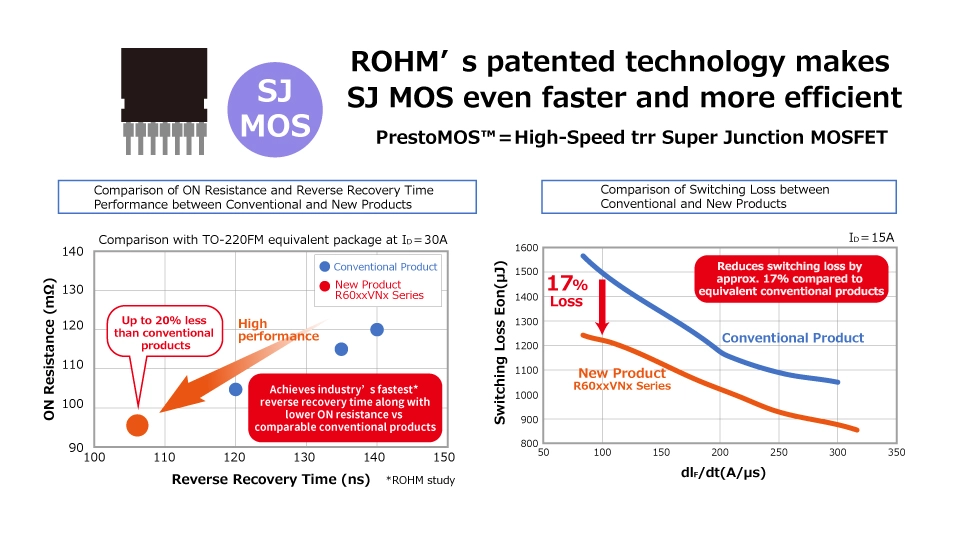

We also propose our PrestoMOS™ lineup that adopts super junction technology for inverter circuits, totem pole PFC and LLC circuits used in solar power generation and other applications. PrestoMOS™ leverages patented technology to simultaneously provide the industry's fastest reverse recovery time together with low ON resistance (which are difficult to achieve at the same time), contributing to greater energy savings in inverters compared to equivalent general-purpose products.

*PrestoMOS™ is a trademark or registered trademark of ROHM Co., Ltd.

3. Reducing equipment size and weight

Along with energy-saving performance, equipment miniaturization is also required.

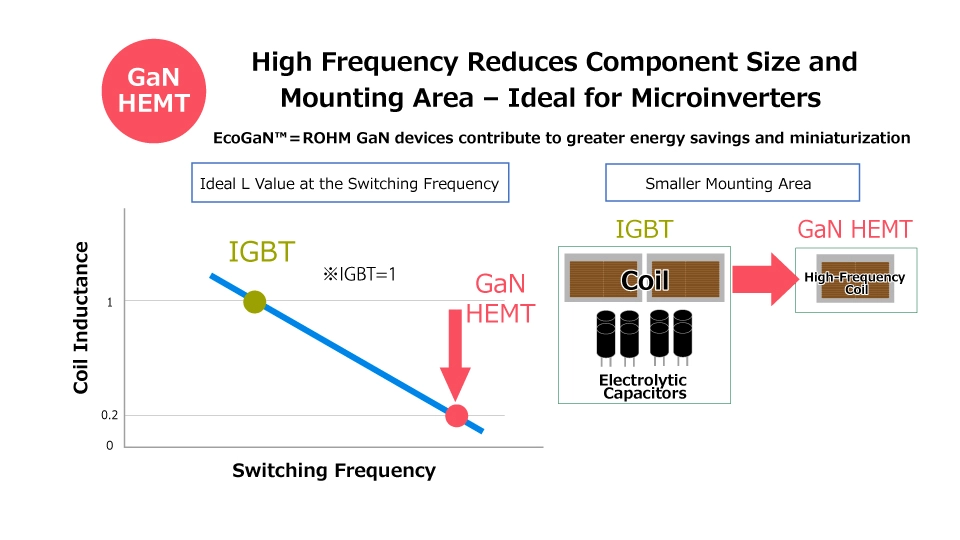

Solar power generation equipment in particular is becoming smaller as the spread of decentralized systems has led to a demand for weight reduction to cut installation costs. In this context, GaN devices are being proposed as the optimal choice for microinverters, which are increasing in popularity as alternatives to existing centralized PV inverters.

GaN devices are gaining market adoption due to their excellent switching and high-frequency characteristics.

At the same time, lower ON resistance vs Si devices is expected to reduce both power consumption and size in many applications.

In PV inverters used in solar power generation equipment, the inductance value L of the coil component that make up the circuit can be further reduced compared to SiC devices by utilizing MPPT (Maximum Power Point Tracking) in the power storage block. This makes it possible to minimize the number of windings and shrink the coil material, significantly decreasing coil size. What’s more, the mounting area can be made smaller over comparable Si devices (IGBTs) by eliminating the need for electrolytic capacitors.

ROHM is working to further improve device performance through its EcoGaN™ lineup of GaN devices that contributes to greater application energy savings and miniaturization.

*EcoGaN™ is a trademark or registered trademark of ROHM Co., Ltd.

Another way is to take advantage of SiC MOSFET’s excellent operating characteristics in high temperature environments mentioned in 1 above. Low heat generation due to low permissible loss enables a reduction in converter weight by decreasing the number and size of heat dissipating components in combination with optimized peripheral devices.

Analog ICs

Similar to power devices, power supply, gate drivers and other analog ICs play a major role in inverter performance.

Power supply ICs that control the voltage required for equipment operation are essential devices that act as the heart of electrical systems.

They play a role in converting to the optimum voltage while ensuring stable supply.

Gate drivers, which control the drive of MOSFETs and IGBTs, perform ON/OFF switching by controlling the gate voltage.

As most of the power loss occurs during switching, they are important for improving energy efficiency.

High withstand voltage is also required, especially in industrial equipment that handle large currents.

Power management ICs

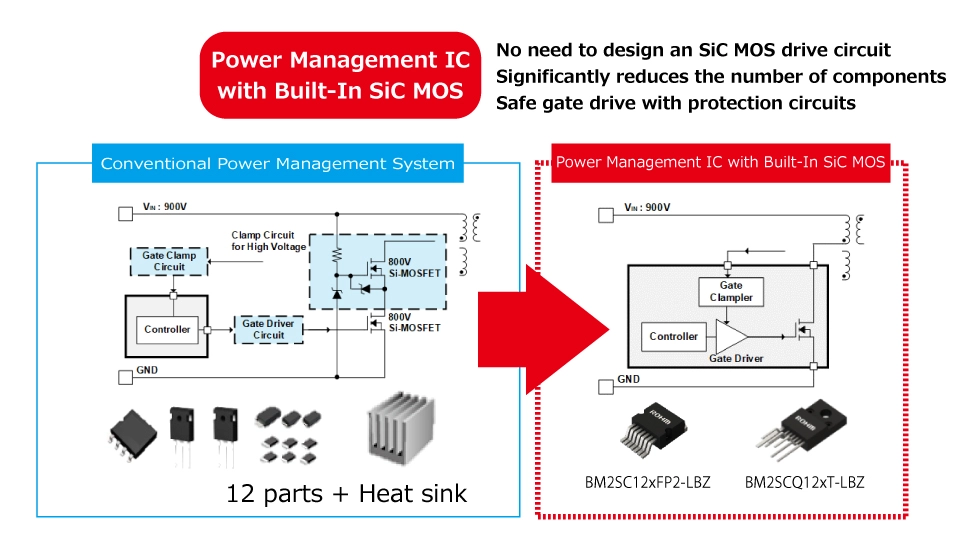

We propose the following AC/DC converter ICs with a built-in 1700V SiC MOSFET for use in inverters.

Integrating SiC MOSFETs into power management ICs eliminates the need for SiC MOSFET driver circuit design, reducing the number of components, while multiple protection circuits provide safe drive operation.

Gate driver ICs

Although providing high performance, SiC MOSFETs and GaN devices require advanced gate driver ICs due to challenges in switching control.

ROHM offers a broad lineup of gate driver ICs capable of optimally driving the various power devices introduced earlier. For example, we are developing specialized gate driver ICs that can maximize the high-speed switching performance of GaN to achieve greater energy savings and reduce application size.

Shunt resistors

Shunt resistors used for current sensing applications are also important devices that contribute to the miniaturization of high-power applications. And as applications become more power-intensive, there is a need for low resistance shunt resistors that support higher power.

Key features for shunt resistors include excellent heat dissipation and temperature characteristics.

ROHM offers the GMR series of low-resistance shunt resistors for applications rated from 4W to 10W, enabling high accuracy current detection even under high power conditions. This contributes to the safety, security, energy savings, and miniaturization of equipment.

Summary

Rapidly evolving to further improve energy consumption efficiency, inverter technology is becoming an integral component in a wide variety of energy equipment, including industrial applications. Inverters convert DC power to AC while optimizing the power supply as needed, reducing energy waste and extending equipment life.

The power conversion efficiency of inverters can be increased even more by using semiconductor solutions tailored to the application and purpose. ROHM contributes to achieving a sustainable society by promoting energy conservation in all types of equipment through the adoption of cutting-edge power devices and analog ICs in inverters.

Product information and related links

Hybrid IGBTs with Built-In SiC Diode (RGWxx65C Series)

Power Management / Power Supply ICs

AC/DC Converter ICs with Built-In 1700V SiC MOSFET

High Power Metal Plate Shunt Resistors (GMR Series)

Industrial Equipment Pioneered by GaN Device & Driver IC

【Satoru Oyama×ROHM Conversational Video】