Driving innovation without compromising on quality for industrial market

06/12/2018

Much has changed during the evolution of ROHM, the Japanese company founded more than 60 years ago to make semiconductors. Business fields and product lineups have expanded; overseas offices have been established; and CSR activities to contribute to society have bloomed. But, at ROHM’s core, its philosophies are unchanged, and quality remains the priority.

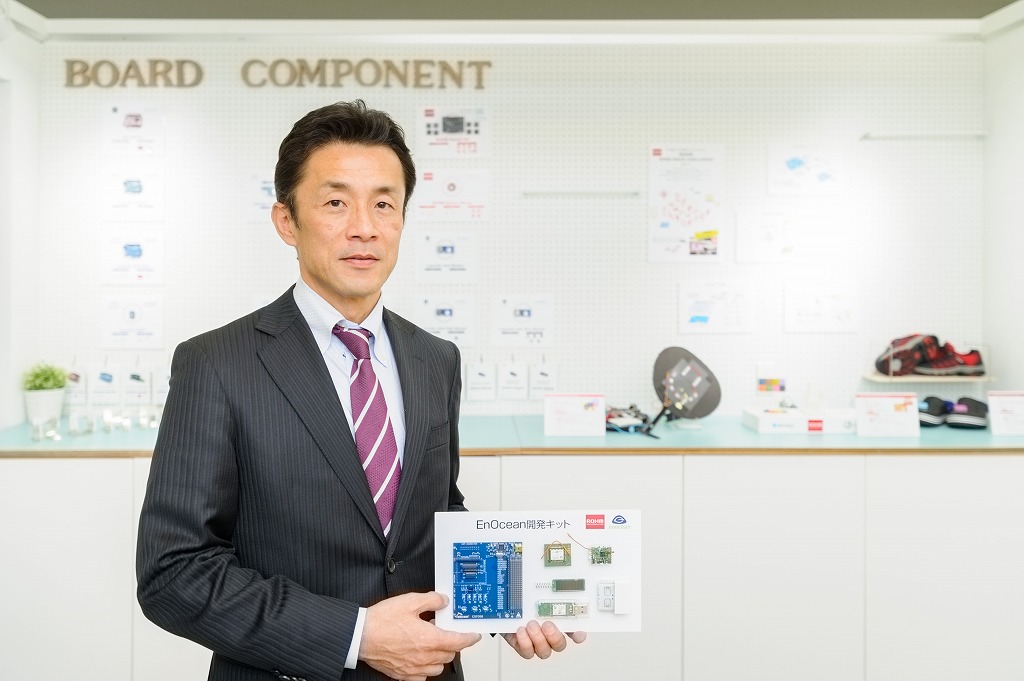

But in today’s rapidly changing business environment and increasingly challenging marketplace, how does ROHM continue to grow while striving for innovation? We asked Tadashi Kanbayashi, general manager of the company’s industrial marketing strategy, for his insight.

Fundamental of ROHM’s quality, he said, is the vertically integrated production system. From silicon ingot pulling to photo mask production to packaging, most of productions is carried out by the company. This process is part of its “Quality First” approach which establishes the customers’ trust.

“Doing a part of the production processes internally and relying on other companies to do the rest result in complicated quality control and corresponding delay in case of occurring troubles,” he added. “ROHM ensure the reliable traceability. We do everything with responsibility to meet the needs of our customers.”

High quality and stable supply is particularly important for industrial and automotive market. ROHM, therefore, maintains and manages the process, and it is less susceptible to external factors. It also results to not only achieve unparalleled quality but also ensures long-term stable supply.

Also creating innovative products, which is important for industrial market, is required close communication with customers. It has done in practice at ROHM since it was founded.

“We listen to customers’ needs and understand their problems by seeing them on the ground. I think the answer is always on site, ready for us to discover,” Kanbayashi said.

In addition, communication with not only customers but also internal engineers is also important. Engineers always share the information each other and continue to learn — from each other, from customers and from the industry.

Six years has passed since ROHM made a full-scale entry into the industrial market in 2012. The company believes that the quality with a particular emphasis has become an advantage with competitors. ROHM produces a number of innovative products with an extensive record of being first in the world, and focus on a growing field such as the smart factory. By embedding ROHM’s various devices such as sensors, wireless communication to applications, we can monitor an environmental and equipment conditions with IoT technology. And visualization of equipment’s condition and utilizing the collected data enable the efficient production and to catch the machine failure in advance.

‘It is expected that the industrial market will grow exponentially in the next few years. For example, I think that infrastructure investment for clean energy and capital investment for xEV will accelerate to increase more and more in the future. Robot arms will become higher performance, making even miniscule parts possible to handle. And, smart factories will become even smarter.’ Kanbayashi said.

At present, parts are produced on an independent production line in each company. Then, various parts are delivered and assembled to applications, and the final product is completed. In the future, however, all factories might be connected by the internet and be able to produce final products without the human resources. If that happens, people can afford the time and will take this time on more creative roles.

Kanbayashi is happy to be leading the work for industrial market in this period of rapid change. For this market, including smart factory, ROHM continues to develop the innovative product and contributes to society in the future with three key word: energy-saving, high-reliability and safe.

Although Kanbayashi has been in charge of marketing since he entered ROHM at 1984, he said that the most important thing is to develop country- or region-specific marketing plans based on its understanding of customer needs. In audio applications, despite compact size is a key factor in many countries, for example, large volume and gorgeous design is preferred in Brazil and India. As a company to supply devices, it is necessary to keep itself open to the differences of demands and changes in each region.

Whatever the market, however, Kanbayashi believes ROHM’s drive to “never give up striving for better quality products” is an attraction for customers. There is a thought which don’t need to improve if it meets a certain standard. Meanwhile, especially in Japan, there are a lot of companies which start to mass production and sale only after meeting the highest quality standard.

Aside from ROHM’s focus on quality, Kanbayshi says it is people who are behind the company’s success.

Of course, although the product itself is evaluated, offering the great support and the hospitality are also the reason why customers choose ROHM. The company always does business on a person-to-person basis and that has a big impact; we can understand and cater to customer needs.

It is fitting that a company founded in 1958, still values the contribution that each person can make in creating a successful, innovative, and high-quality business.