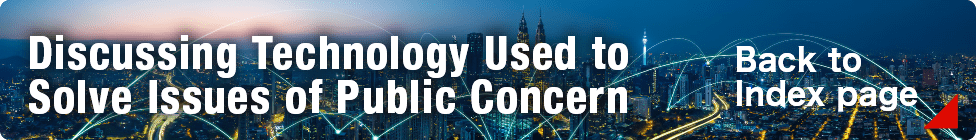

A society that utilizes data is one that consumes large amounts of electricity. We have entered an era in which vast quantities of data are collected in both virtual and real-life environments, such as factories, and then used extensively. Data centers with tremendous processing power create new value from these huge amounts of data to transform lives and industries. However, keeping data centers operating reliably requires a massive amount of power. We discussed the future of data center power systems with Victor Avelar from Schneider Electric, a leader in digital transformation in the energy management and automation sectors and provider of reliable and efficient power system for data centers, and Ming Su of ROHM, a major supplier of semiconductors for power supply circuits.

Ming

There is a great push under way to use data to create fulfilling lives, innovative businesses, and solve social issues. Data centers are playing an increasingly important role in achieving these goals. Both ROHM and Schneider Electric play their part in helping data centers operate more reliably and efficiently - ROHM by offering power supply ICs and power devices that contribute to greater system efficiency, and Schneider Electric by supplying and managing the power infrastructure.

Avelar

I lead a department called the Data Center Science Center in Schneider Electric’s Secure Power Division, reporting directly to the CTO office. Our role is to anticipate future data center trends, determine their impact on data center operations management, and identify underlying technological trends. We are also investigating issues emerging in existing data centers and the technologies designed to solve them. We then summarize our findings on current states and ideal situations in white papers which we offer to clients to use when making decisions, such as selecting technologies for data centers and making investment decisions. As the director and senior research analyst, I am responsible for researching technological trends related to design and management in order to maximize the efficiency and availability of data centers.

For example, Schneider has a wealth of technological expertise of the subsystems that make up data centers, such as a UPS (Uninterruptible Power Supplies) . However, it is generally not known how to select the most suitable UPS for a data center based on various viewpoints. Therefore, it is our job to provide simple explanations from the client’s perspective.

In addition, we offer web-based tools called ‘Trade-Off Tools’ that allow clients to quickly understand the trade-offs associated with different data center designs. For example, clients can use these tools to calculate the capital costs of a data center to make sure it stays within budget.

Ming

ROHM is a semiconductor manufacturer that utilizes a vertically-integrated development system in which all processes, from wafer production and circuit design to layout and packaging, are conducted completely in-house. This gives us the flexibility to handle all aspects of semiconductor technology and allows us to offer devices, modules and systems that satisfy individual user needs.

We also have a development system for providing solutions in line with client requirements in the global market. In addition to research and development locations in Japan, ROHM has established an R&D facility in Germany called the ‘Power Lab’ designed to meet the latest technological needs in the automotive and industrial equipment industries, as well as support bases in key areas in Asia and the US dedicated to solving customer issues. I work in the Michigan branch of ROHM Semiconductor, where we focus on a number products such as power semiconductors and sensors that can be used effectively in data centers.

The ever-growing power consumption of data centers

Avelar

Now that we are in an era where vast amounts of data are generated both online and in places like factories, data centers face several serious challenges.

For example, data centers are increasingly being established near automotive and other factories to augment IoT in production lines, a concept called Industry 4.0. The amount of data generated is skyrocketing, which in turn is rapidly increasing power consumption. 5 years ago, the power consumed per server rack was 2-3kW (kilowatt). This number has now climbed to 5-6kW. The reason is because high-performance chips such as GPUs that consume a lot of power are being introduced to process the large quantities of data.

GPUs used for data processing consume 300-400W of electricity per unit. Many GPUs are deployed simultaneously at a data center, which alone consumes a significant amount of power. Furthermore, GPUs are densely packed together on circuit boards inside server racks, so even the cooling systems that dissipate heat from each chip consume a lot of electricity. Moreover, data centers must run continuously around the clock, meaning that the servers must be constantly cooled as well. To maintain this state of constant operation, it is essential to use an Uninterruptible Power Supply (UPS) to provide a stable supply of power needed. Then of course the UPS itself uses a certain amount of power.

There appears to be no end to the rise in the quantity of data that requires processing. This in turn increases the amount of heat generated. In the future, expectations are high for the introduction of liquid cooling systems with excellent cooling efficiency that can reduce power consumption even further.

Ming

To address challenges associated with the rapidly growing amount of power consumed by data centers, ROHM offers technological innovation at the device level.

According to one study, as much as 400TWh (terawatt hours) of power is consumed around the world per year. Data centers are using more and more power, and continuing this trend will certainly cause problems that can lead to a surge in global power consumption. However, in actuality only half of the power consumed by data centers is used for IT-related processing. A lot of energy is spent on cooling or due to power loss, which is hardly an efficient use of electricity. Therefore, ROHM believes that reducing this waste is a matter of first importance.

Of particular importance is minimizing power losses in the UPS. With continuous inverter supply (online) UPS that can provide high-quality power with no fluctuations (i.e. voltage according to load), double conversion (converting power twice) technology that ensures consistent supply is typically used. However, although this method does deliver stable high-quality electricity, the high number of conversions results in greater power loss, which is a major drawback. For UPS configured with conversion circuits utilizing existing Si-based (silicon-based) power semiconductors, it is rare for the conversion efficiency to reach 95%. And this efficiency drops even more under light-loads.

At ROHM, we are proposing semiconductor applications that replaces silicon with a new material called silicon carbide (SiC). Switching from the Si-based IGBTs currently used as switch elements to SiC devices dramatically increases UPS efficiency to 98%. Moreover, this high efficiency is maintained until the load drops to light conditions of 20-30%.

Striving to increase data volumes while keeping power systems both efficient and reliable

Avelar

Schneider Electric is also looking at SiC-based power semiconductors as one of the technologies that can reduce a data center's carbon footprint (emissions of greenhouse gases such as CO2). Our goal is to create sustainable data centers that maximize energy efficiency. Naturally, the greatest priority for our client companies is the stable operation of data centers in the face of ever-increasing amount of data. However, in order to continue using data in even more sophisticated ways, it will be necessary to invest in solutions that achieve higher energy efficiency. I believe we need to focus on both efficiency and reliability by adopting a variety of technologies from the semiconductor device level to the power system level.

Ming

SiC is a high-performance material that has attracted much attention not only for industrial equipment such as UPS, but solar power generation (PV), electric vehicles (EV), and other applications as well. Among these, the demand for EVs is expected to be large due to the ‘EV shift’ currently progressing worldwide. A full-scale mass production system for EVs has been established, and once its effects are seen the barrier to application can be lowered. This will accelerate the adoption of SiC power semiconductors in data centers, leading to dramatically reduced conduction losses in UPS while also achieving greater space savings and making systems more compact by increasing switching speeds.

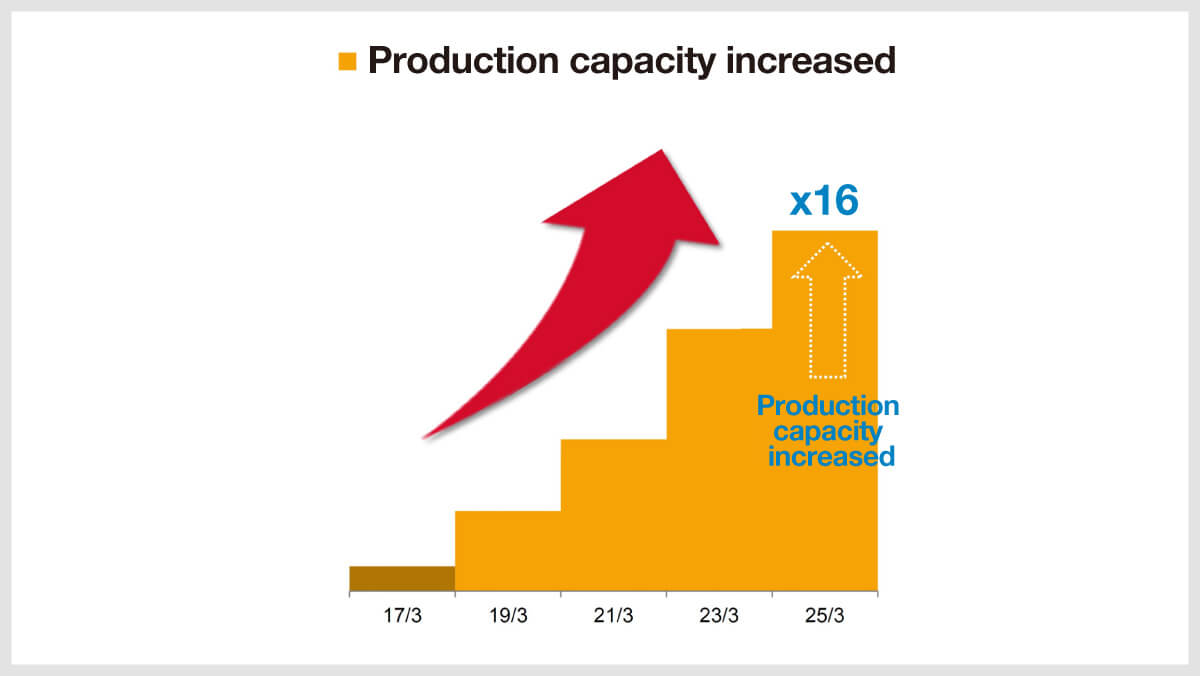

ROHM, a leading supplier of SiC power semiconductors, was the first in the industry to mass-produce SiC MOSFETs in 2010. Later, we introduced 600V to 1200V SiC MOSFETs featuring a trench gate structure ahead of other companies, designed to meet the needs of a wide range of markets - not just UPS. To establish a supply system that can respond to the growing demand, ROHM is investing a total of 60 billion yen in SiC power semiconductor factories from 2018 to 2023 that will increase production capacity by 16 times compared to 2018.

Focusing on predictive maintenance using sensors and 48V switching rack supply voltage

Avelar

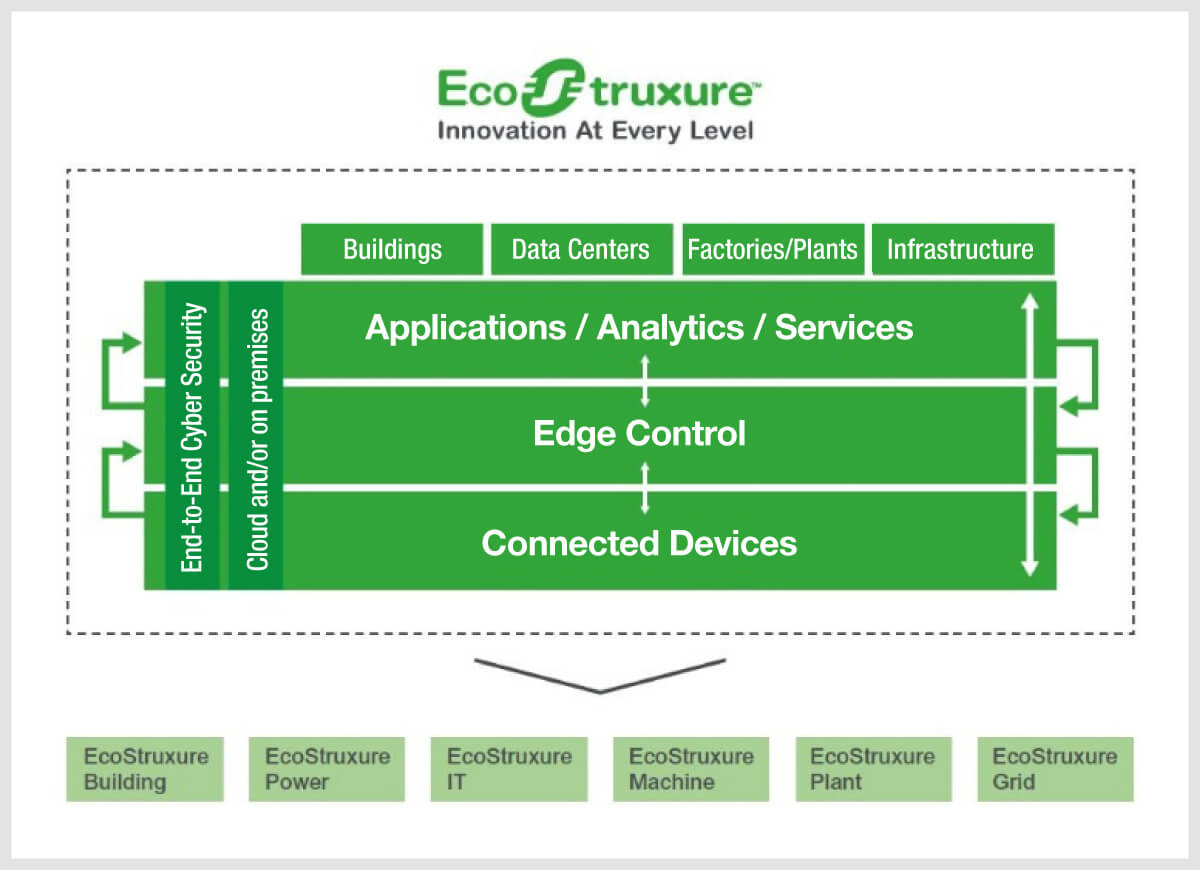

Schneider Electric offers ‘EcoStruxure’, a cloud based IoT-enabled platform and architecture, that allows for plug-and-play, open, interoperable solutions in buildings, data centers, factories/plants, and public infrastructure. EcoStruxure for Data Centers, which supports the efficient operation of data centers, is a platform that connects many of our products and controls and manages data centers not only in terms of operational efficiency, but from an availability perspective as well.

UPS incorporates multiple sensors, and thanks to falling sensor prices, it is now possible to use a larger number and wider variety of them. This allows users to monitor a variety of parameters such as temperature, humidity, voltage, current, vibration, and rpm (revolutions per minute). And one day machine learning and AI will be able to detect signs of malfunctions before they occur. This is expected to eliminate the need for client company engineers to search for the cause of failure. At the same time augmented reality (AR) would presumably be used to show them how to repair it.

Apart from this, we are also focusing our attention on 48V power supplies to optimize power efficiency in data centers. This idea was first proposed by Google. Then later, at a regional summit held in September 2019 by the Open Compute Project (OCP), a non-profit organization that promotes the open source of blueprints and specifications for hardware such as servers, the supply voltage of the OpenRack V3 standard specifications was chanced from 12V to 48V. This virtually guarantees that the voltage supplied to racks will switch to 48V.

Ming

ROHM has released a step-down DC/DC converter IC compatible with 48V system power supplies for servers. Proprietary Nano Pulse Control technology is used to achieve a high buck ratio of 24:1 by reducing switching noise and enabling high-speed 9ns pulse drive. This technology allowed ROHM to develop a groundbreaking converter that can stably reduce voltage from 48V to the 2.5V required by processors and the like in a single step. Applying this to server power supply systems could potentially save space on racks and circuit boards while helping to simplify circuit configurations.

Transforming data centers through edge computing

Avelar

Edge computing is another major trend we are seeing in information systems these days. Many stakeholders of data centers are watching this trend closely as it could greatly affect the processing power, scale and location of future data centers. Right now, there is a push to use edge processing in applications such as augmented reality (AR), self-driving vehicles, telemedicine, and retail to reduce latency (delay) and bandwidth usage costs.

Ming

Micro data centers process less data than regular data centers, but there will a large distribution of micro data centers. So it seems that new technological concepts different than the ones we have now will be needed.

Avelar

Exactly. One of the technological issues we are facing at Schneider Electric is figuring out how cooling, supplying power, and performing maintenance should be carried out with edge computing.

Although edge computing is sometimes carried out in an IT environment, it is often implemented in commercial facilities and factories, as well as harsh natural environments like deserts and oil fields. We must also think of new ways to increase the power efficiency of micro data centers. And new concepts are required for maintenance systems. This is because micro data centers must be designed based on the premise that there will be no IT personnel present. We have to assume that the power supply status will be monitored remotely. As Schneider Electric expects to manage thousands of data centers collectively, we provide a mechanism that supports batch management through our EcoStruxure cloud platform.

Ming

New needs will probably arise for power systems as well. First, even though they are small, micro data centers cannot be allowed to fail, so they will require a stable supply of high-quality power. Moreover, the power supply needs to be efficient without taking up space. Therefore, UPS solutions on the edge side will also require semiconductor technology with excellent power conversion efficiency.

Avelar

Yes, we can expect to see SiC used here as well. Micro data centers face another major issue: cooling. Currently, direct expansion cooling systems are used, or if not available, residential AC. But both of these options consume a large amount of electricity, which is a cause for concern. Therefore, adopting liquid cooling systems here as well is emerging as a possible alternative if we want to reduce the carbon footprint of micro data centers.

Environmental considerations are essential when introducing technology in next-generation data centers

Ming

The reason we have such high expectations for SiC is because reducing losses during power conversion also has the effect of decreasing the amount of heat generated. Cooling systems in data centers consume enormous amounts of power, so reducing heat generation is expected to achieve dramatically lower power consumption. This will also make it possible to decrease the size of servers by simplifying cooling components, which will allow for a greater number of machines per unit area and increase return on investment.

Avelar

It would great if engineers in the IT field joined those in the semiconductor field in focusing their efforts in this area. Even when different programs perform the same function, some code can be messy while others are more intelligently written that takes carbon footprint into account. For example, smartphone software is very efficiently programmed to run on minimal power. The same holds true for SiC, where there is a need for approaches that accomplish more with less.

Data, which will only continue to increase from now on, must be used effectively and efficiently. At Schneider our goal is to not only increase the availability of data centers, but also operate them efficiently, making sustainability a major target. We want to achieve this through power management at data centers and beyond.

Ming

Right now, the focus tends to be on how to provide the processing power required to handle the ever-growing amount of data. However, we must not forget that increasing the processing power must be accompanied by a stable supply of power and the further optimization of energy. We are living in an age where movies can be downloaded from anywhere, but few people consider how much power is consumed in the background to provide this extra bit of convenience. Therefore, to develop fulfilling lifestyles and a prosperous society, we must establish a mechanism to make these sustainable. Focusing on the Sustainable Development Goals (SDGs) set by the UN allows ROHM to contribute to achieving a sustainable world by providing semiconductors that make power systems more efficient.

- Data Centers That Cannot Be Shut Down, Even for an Instant -

Contributing to stable operation through high energy efficiency

Data centers have become indispensable for achieving affluent lifestyles and solving numerous social problems. It can be said that they are the ever-beating heart of our modern society. And their importance is only likely to continue to rise in the future, along with further improvements in processing capacity. Meanwhile, we are faced with the dilemma that this increasing power consumption could actually become a factor behind social problems.

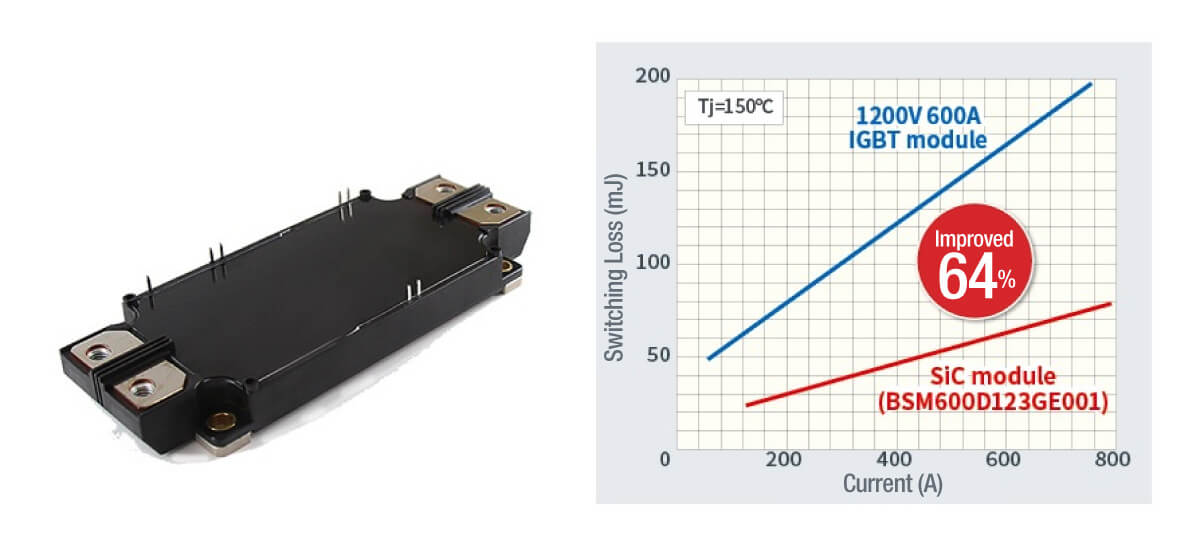

ROHM offers the 1200V, 400A/600A rated full-SiC power modules BSM400D12P3G002 and BSM600D12P3G001 capable of significantly reducing power loss in inverters and converters used as the core of an uninterruptible power supplies (UPS). As such they are expected to contribute to the stable operation and reduced power consumption of data centers.

The modules feature a redesigned package leveraging an original internal structure and optimized heat-dissipation design to achieve a 600A rating that supports the high-capacity power supplies required by data centers. In order to ensure a high current rating, it is necessary to reduce the inductance inside the package to handle the increase in surge voltage during switching operation. ROHM has succeeded in reducing internal inductance by approximately 23% by optimizing the embedded SiC device layout, internal pattern, and terminal structure. In addition, improving the flatness of the base plate portion that significantly contributes to the heat dissipation of the module makes it possible to reduce the heat resistance between the module and the cooling mechanism by 57%.

The modules are equipped with ROHM SiC MOSFETs and SiC Schottky barrier diodes (SBDs). As a result, switching loss is reduced by 64% (at a chip temperature of 150°C) compared to general IGBT modules with equivalent current rating. Furthermore, taking advantage of the characteristics of SiC to enable high-frequency operation makes it possible to use smaller peripheral components. In addition, the lower heat generated during operation translates to smaller cooling systems. This allows designers to reduce the size of the heat sink by up to 88% when driving at 20kHz. Combining all of these effects helps make UPS more compact.And going forward, ROHM will utilize the superior energy-saving effects of SiC devices to support the development of a data-driven society.

1200V 400A/600A rated full SiC power modules that contribute to lower power loss in uninterruptible power supplies (UPS) for data centers: (Left) Module appearance, (Right) Comparison of switching loss vs IGBT module with equivalent current rating